- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

Top 5 Dental Lab Products Articles of 2020

Innovations, partnerships, and enhanced material options are among the most popular content on the Dental Lab Products® website this year.

Returning to print publication over the summer, Dental Lab Products® spent 2020 ramping up operations with a new focus on sharing news from and for dental labs, showcasing technical work and workflows, and examining industry trends.

Even with the coronavirus disease 2019 (COVID-19) pandemic disrupting everything throughout the year, this remains an exciting time for the dental lab industry. New innovations and enhanced material options continue to drive new ways for labs to work, and yet new opportunities also bring new challenges, all of which we endeavor to cover.

With that in mind, what follows are the 5 most popular articles from the past year.

Keystone, Henkel Announce New Partnership

It’s certainly been a big year for news in the dental lab space, and 3D printing’s continued evolution and advancement plays a major role in that story. This partnership announcement is really about where 3D printing is heading, as the race for better, faster, stronger, and more lifelike materials is running as fast if not faster than the advancements in 3D printing technologies. Keystone Industries and Henkel hope their collaboration pushes the materials side of this equation farther and faster than anyone else.

Go to bit.ly/KeystoneHenkel

How to Balance Digital and Analog Design

by Conrad Rensburg, ND, NHD

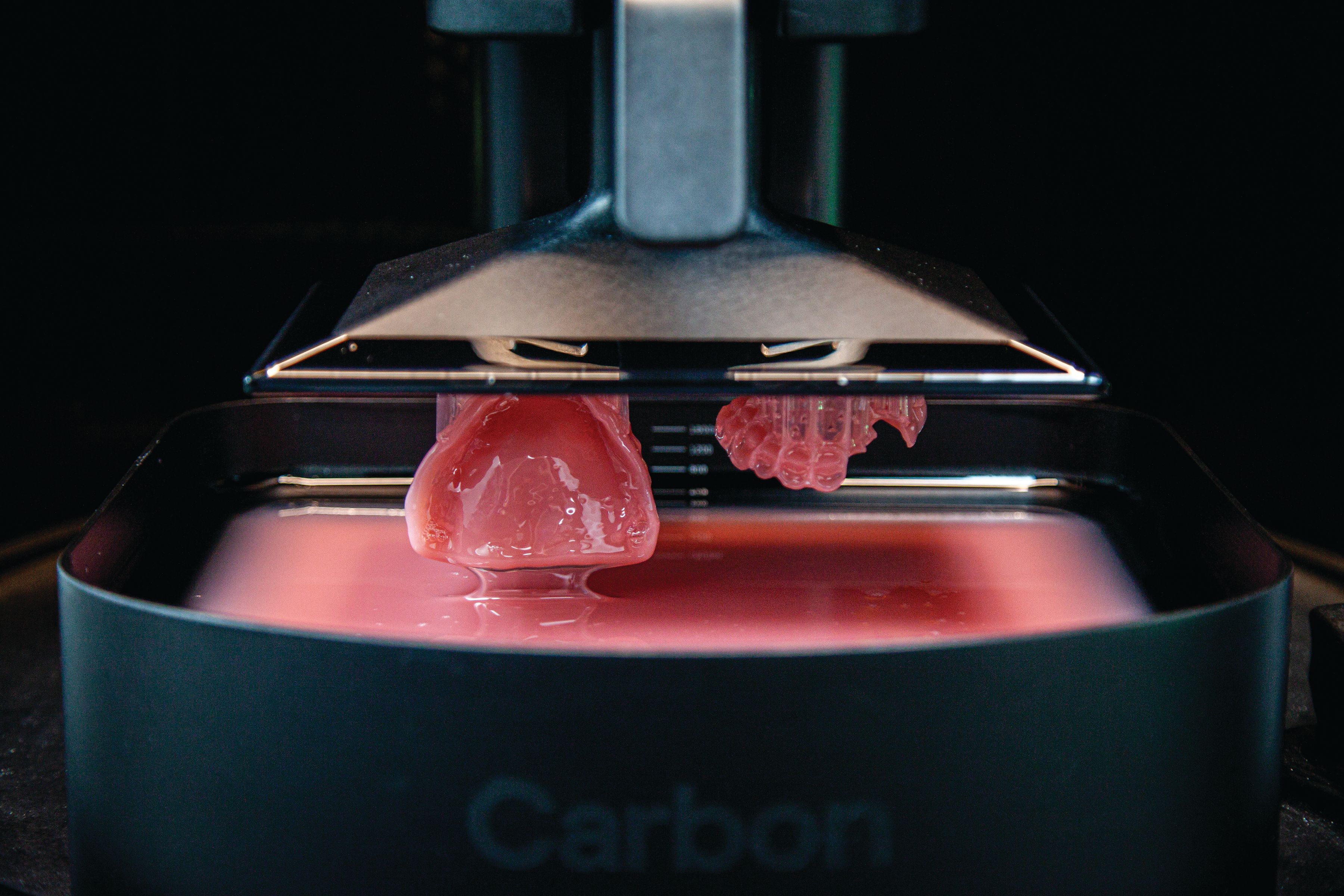

Part technique, part dissertation on the future of removables, this article from editorial advisory board member Conrad Rensburg shows how he pushed his equipment to dial in his workflow for digital partial dentures. Using 3D printing and other digital approaches, Rensburg approached the case with an analog mind-set and customized Dentsply Sirona’s Lucitone platform, which was originally designed to just fabricate complete dentures. Rensburg details his creative solutions to use the Lucitone materials and Carbon 3D printing technology to design and fabricate a removable partial.

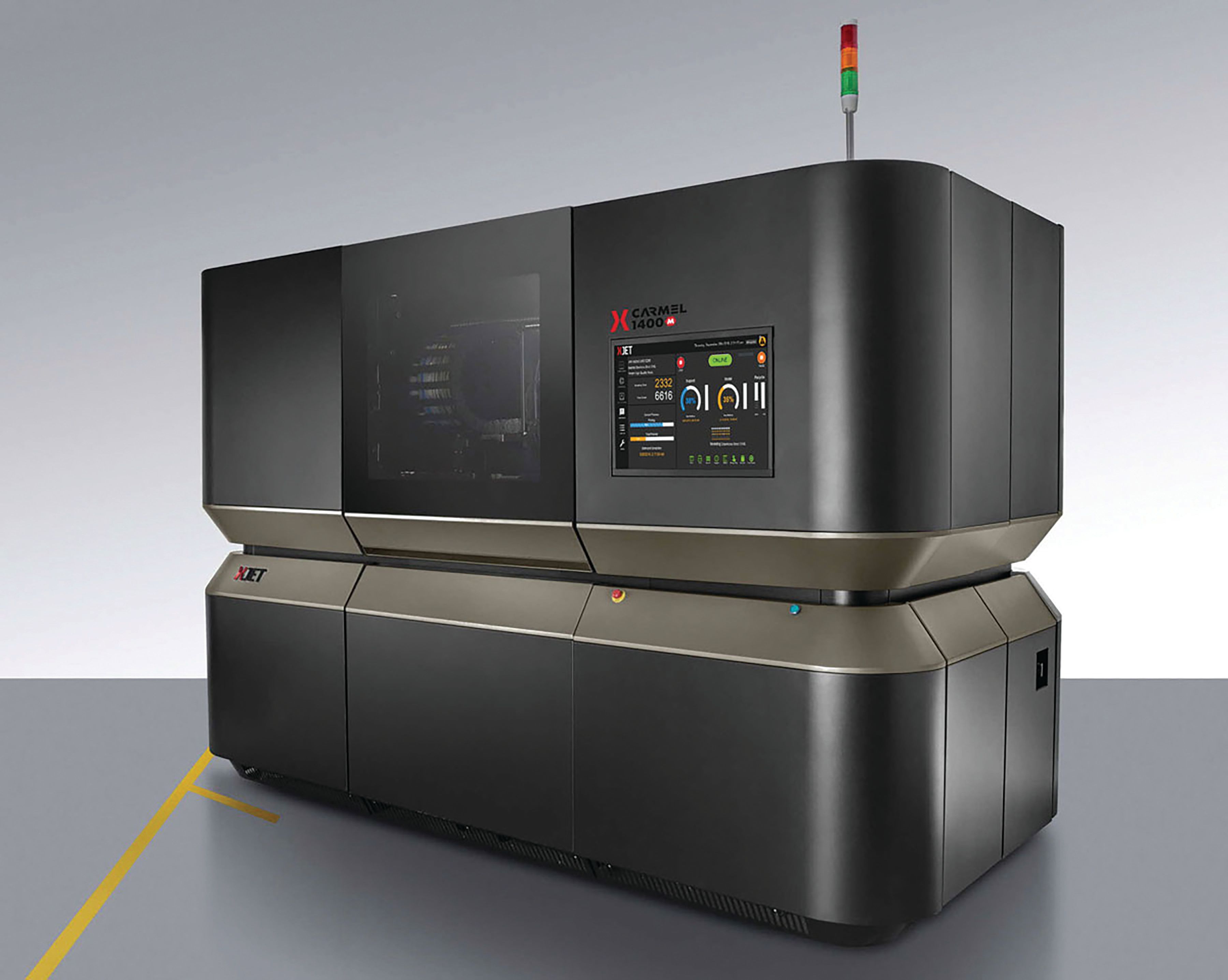

XJet, Straumann Partner to Advance AM Technology

As described in a popular news item about a partnership focused on the future of 3D printing, Straumann Group and XJet Ltd plan to work together on 3D printing of ceramics specifically for end-use parts. Additive manufacturing is developing at a rapid pace, and news about this sort of collaboration is worth watching because these technologies could be the future of crown and bridge production.

Go to bit.ly/StraumannXJet

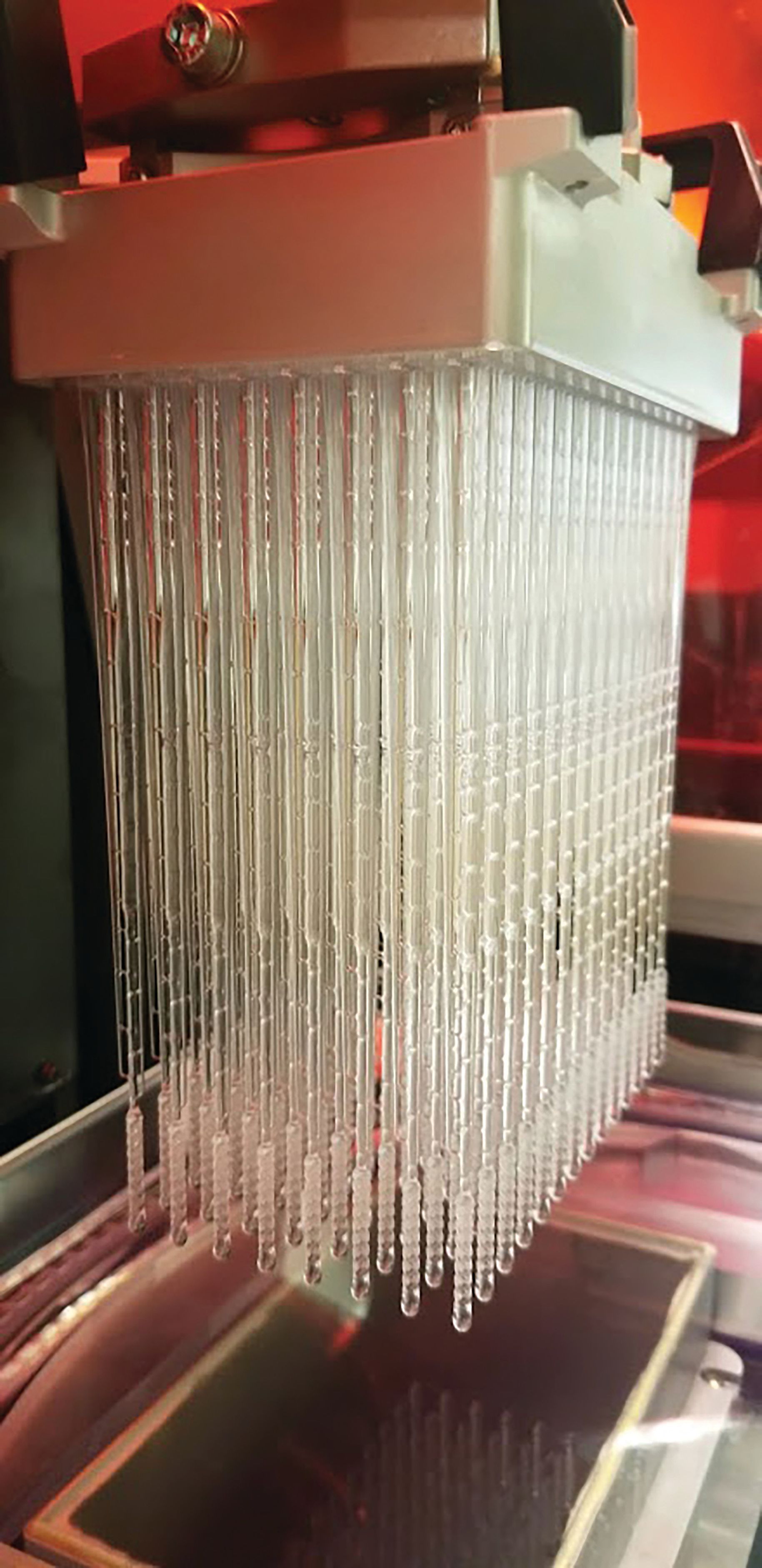

Whip Mix Begins Manufacturing, Distribution of Critical Nasal Swabs

Another well-read news item about 3D printing discusses how Whip Mix stayed busy during the COVID-19 pandemic by helping to meet demand for critical supplies. The manufacturer worked with local health authorities in its home state of Kentucky to design a 3D printed swab for COVID-19 testing. This particular article proved the most popular among what was a parade of news about how dental labs and dental manufacturers found ways to help their communities during the pandemic.

Go to bit.ly/WhipMixSwabs

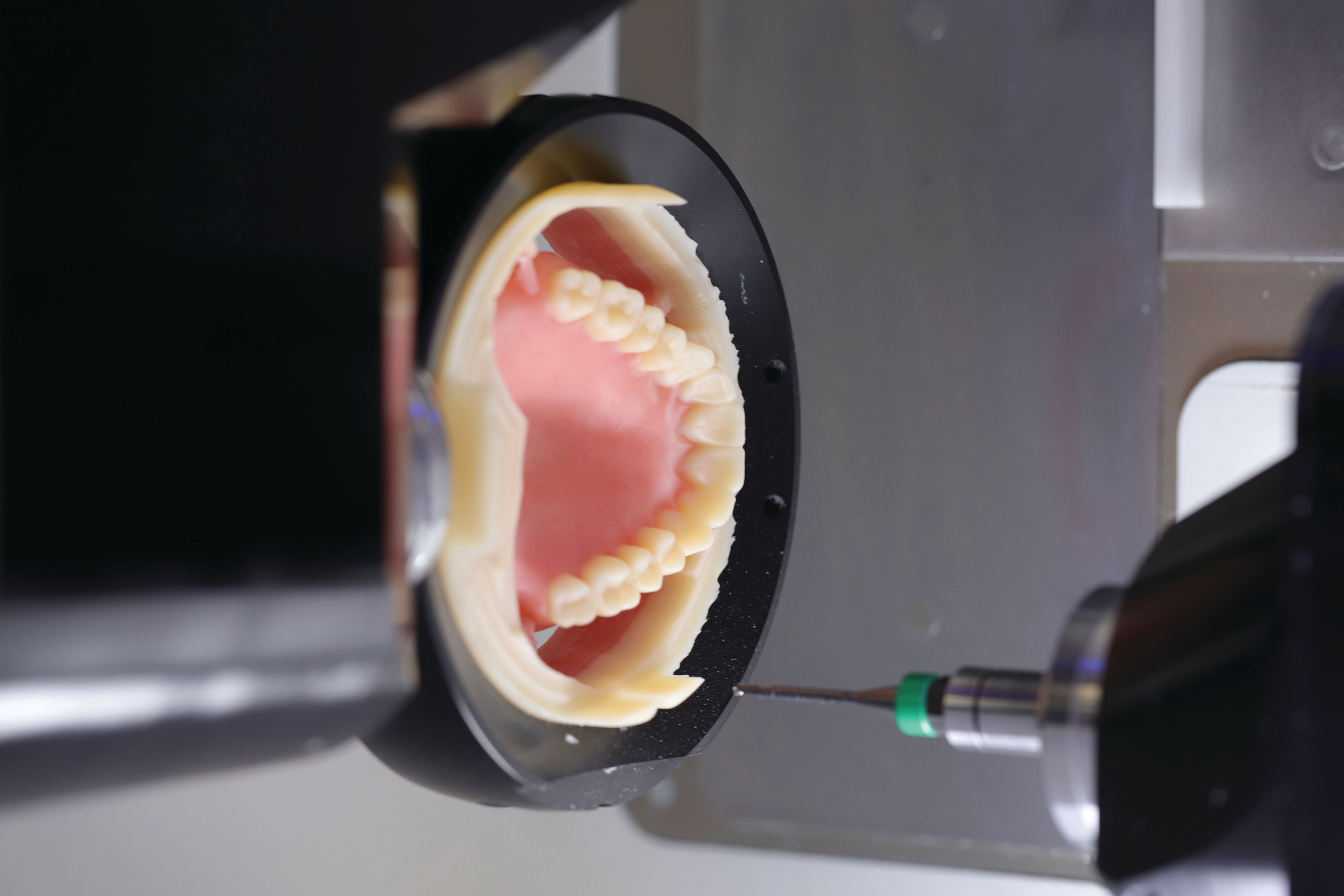

How to Perfect a Complete Digital Manufacturing Process to Create Top-Quality Removable Dentures

by Eric Kukucka, DD

This article from Eric Kukucka—the only one on this list not focused on 3D printing—highlights another technique showcasing innovations in the field of removable prosthetics. Kukucka demonstrates what can be done with Ivoclar Vivadent’s Ivotion material. This milling disc features 2 materials that allow the gingiva and the denture teeth to be milled simultaneously, creating a monolithic digital denture. The technology powering this mixes advanced software with cutting-edge material science to create a new process to simplify denture creation.

Go to bit.ly/Ivotion

Download Issue: Dental Lab Products December 2020

Download Issue: Dental Lab Products December 2020