- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

Top 10 DLP Articles of 2022

The top 10 articles published in Dental Lab Products® in 2022.

Articles about new products once again led the way this year, with 3 5Ws* (on the who, what, when, where, and why of new products) making the cut. Our readers also wanted to learn about 3D printing and 3D-printed dentures. The April cover story, on the artistic side of dental labs, made the list too, as did 2 other features—one on side hustles for dental labs and the other on how to build strong relationships with client practices. A piece on how dental materials are used in other industries was likewise popular with our audience.

5Ws* IMPRESS3D Digital Valplast

Compiled by Kellie Nock

These digitally designed, 3D-printed partials allow dentists to offer patients technology-enabled, flexible, removable dentures that are said to fit the first time. The dentures are fashioned to simplify practice workflow and reduce chair time from digital scan (or impression) to device fitting to 2 visits or less. IMPRESS3D uses patent-pending processes to ensure the strongest bond between the teeth and the partial denture. The company’s proprietary software enables dentists to sign up, upload, and submit a case in under 3 minutes and receive a finished, high-quality Valplast partial that requires little to no adjustment in less than a week.

Video Interview: Building the Next Phase of Dental 3D Printing

Hosted by Noah Levine

Dental Lab Products® Editorial Director Noah Levine interviews Stef Vanneste, general manager and vice president of 3D Systems, about the technology’s current and future role in the industry. They also discuss why more general practitioners are not using 3D printing and how DSO and group practices may propel its wider adoption.

5Ws* DLyte Desktop Dental

Compiled by Kellie Nock

DLyte Desktop Dental’s compact machine makes for faster, safer, and more efficient polishing of cobalt chrome pieces. Because the system does not require preexisting or compressed air installation, it is relatively easy to install and accessible for most dental labs. Its size (450 × 521 × 471 mm) means that it is suitable for smaller as well as larger labs. DLyte Desktop Dental also comes with software to assist technicians in the polishing process.

.jpg?fit=crop&auto=format)

Closer Look: An Inventory Solution That Controls Costs and Parts

by Stan Goff

In this article, BJ Kowalski, president of ROE Dental Laboratory, explains why his lab began using the Zimbis Tower system, which offers a solution for storing, dispensing, and managing implant components, precious metals, and other expensive supplies. The Zimbis cabinets connect to lab management software to ensure accurate tracking of all prosthetics and automatic restocking of supplies.

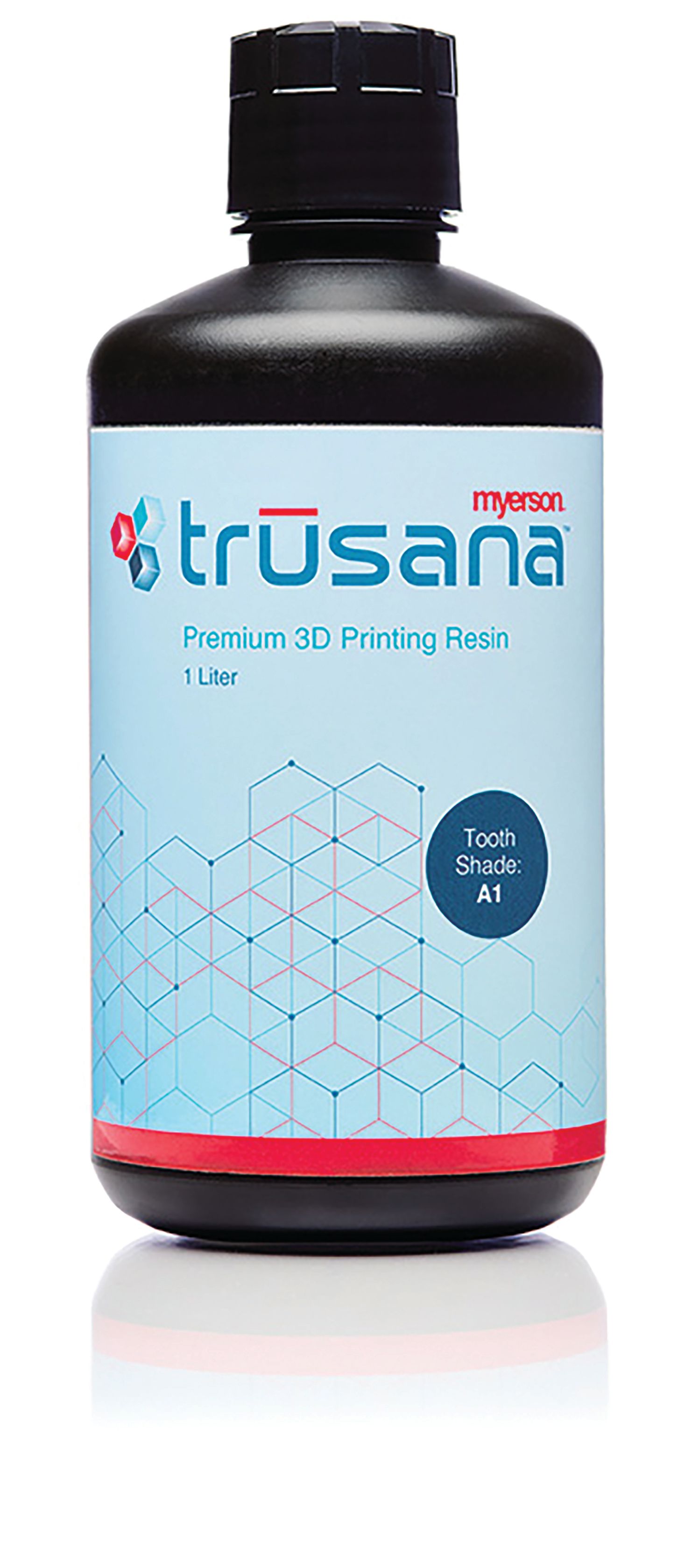

3D-Printed Denture Material Showcases Strength and Esthetics

by Kellie Nock

Trusana Premium 3D Printing Resin, a photopolymer liquid for dentures, was formulated to fill the gap left by materials that were prone to breakdown. The new resin is durable and offers the enhanced esthetics that patients want. Its water uptake is lower than that of many similar products on the market, and it is available in 6 shades—A1, A2, A3, B1, C1, and 51 (bleached)—for esthetic flexibility.

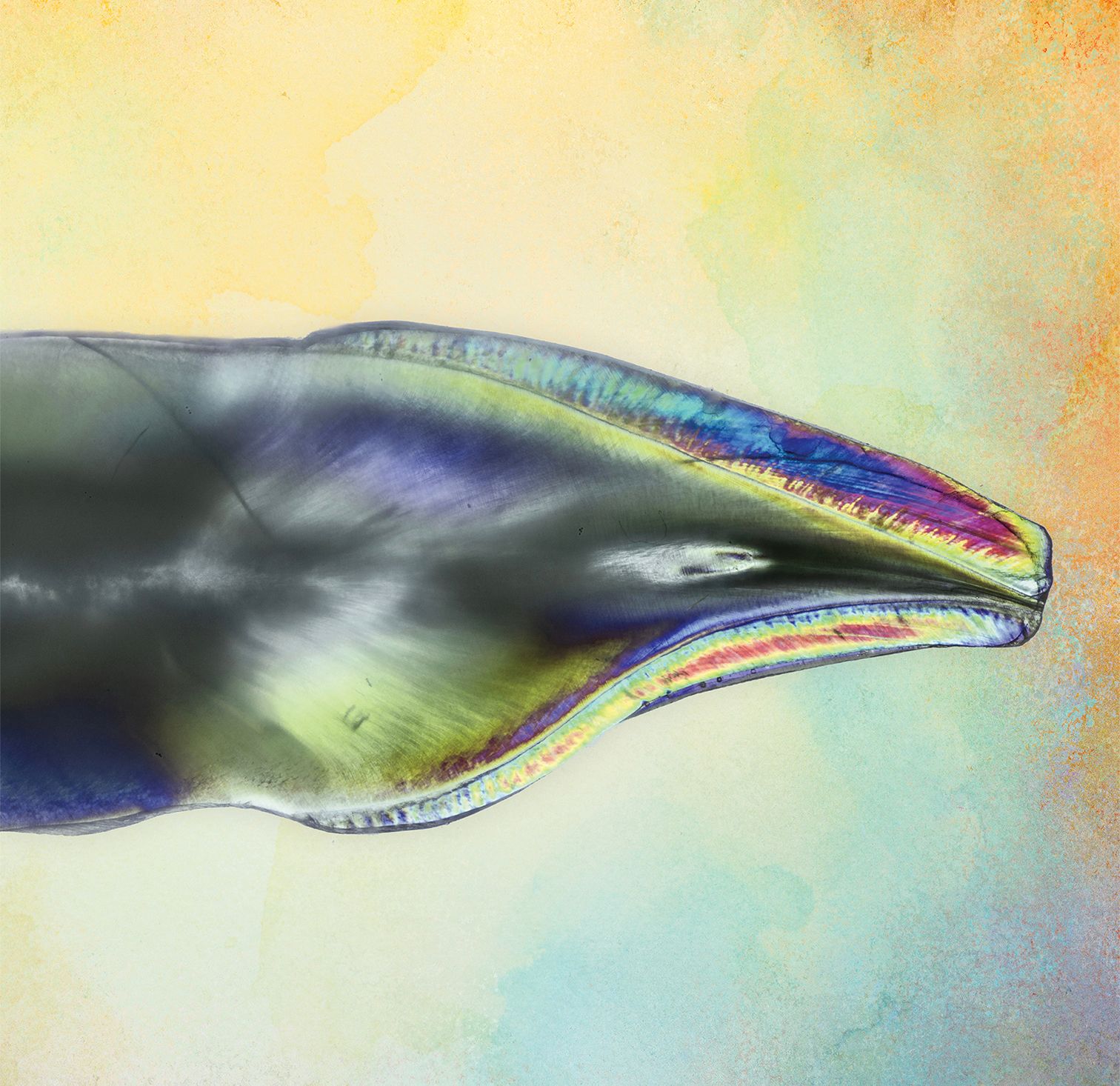

Where Inspiration Strikes

by Robert Elsenpeter

Our April cover story focuses on the artistic side of dental labs. While crafting a restoration, technicians must follow certain guidelines to ensure proper fit and function. But that doesn’t mean that there is no room for artist license. Inspiration can come to a technician anytime, during a conversation with a colleague or while working on a unique case. Likewise, there is no limit to how creative lab technicians can benefit the industry.

Bolster Lab-Client Relationships With Expert Advice

by Terri Lively

Relationships are the key to a thriving business. In this article, dental lab experts share their secrets for solidifying connections and strengthening the lab-client bond. Being a resource for clinicians—by offering new and better products, technology, and workflows—is therefore crucial for labs. Two-way communication is also essential, and expectations must be discussed.

Never Slow Down: Ideal Side Hustles for When Dental Lab Business Is Slow

by Laura Dorr

Summer is the time for vacations, recreational activities, and getting out of the office. But it’s also the time dental labs dread: the slow season. Although business always ebbs and flows, at certain times labs can expect to be less busy. Nevertheless, they don’t have to take a huge economic hit. There are plenty of opportunities to make extra income outside the lab and also options for owners who want to keep their side hustle dialed into the industry.

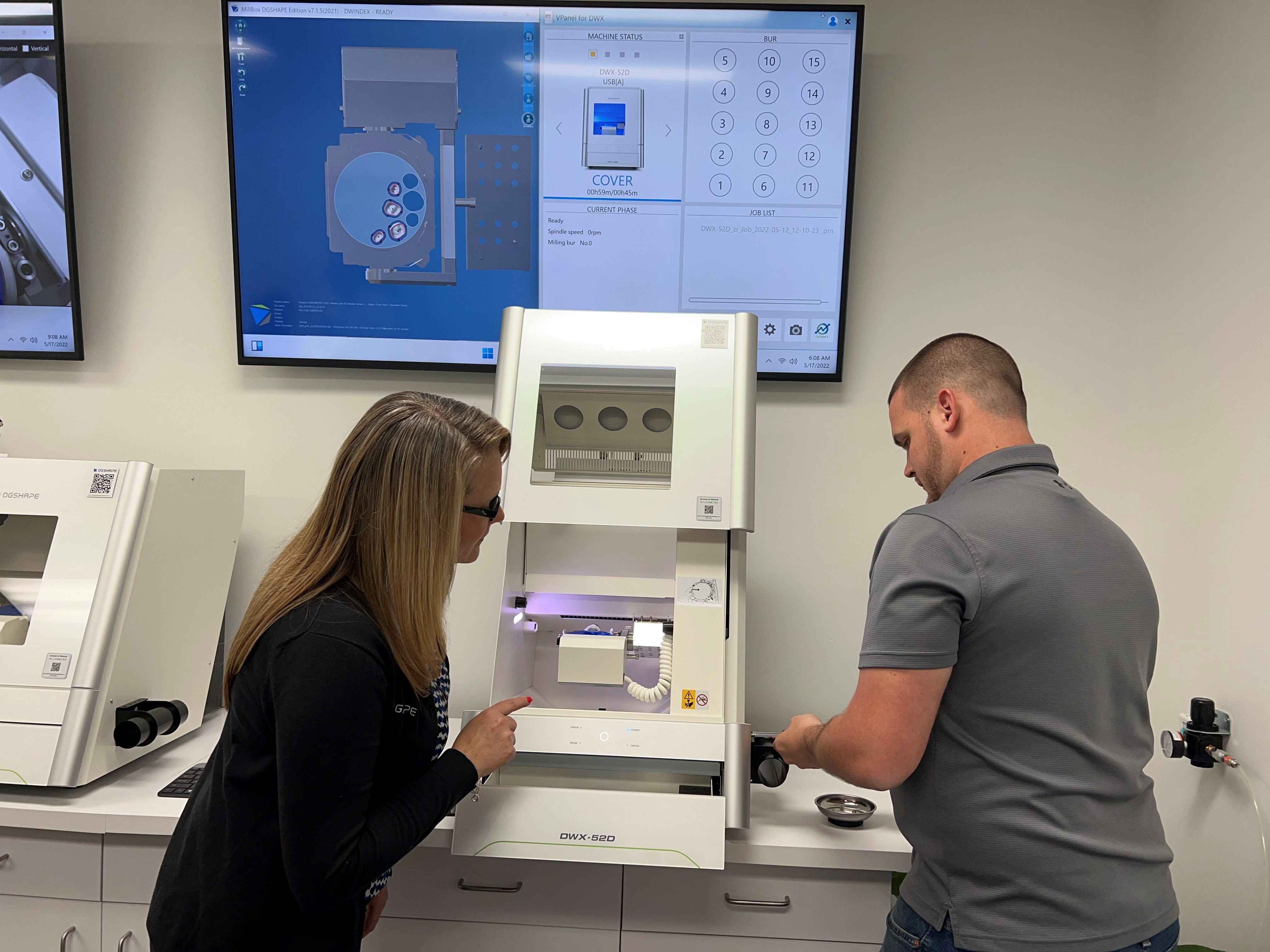

5Ws* Origin One Dental

Compiled by Stan Goff

The Origin One Dental 3D printer makes possible the mass production of dental parts with a variety of high-performance materials. Powered by Programmable PhotoPolymerization (P3™) technology, the printer produces accurate and consistent parts. Its open architecture will support additional materials over time and offers flow production for leading application with specific materials from the Stratasys network. The materials available are designed to attain the best print speed without sacrificing strength.

How Dental Materials Get Used By Other Industries

by Noah Levine

Dentistry is truly a materials industry that is always searching for new options that can provide the ideal combination of strength, color, translucency, and durability. Even as the latest materials are closer than ever to replicating the physical properties of teeth, the choice often comes down to a balance between strength and esthetics. However, dentistry is not in itself a huge industry, and many of the materials it uses were not specifically developed for it. In most cases, the materials are used widely in other industries—often in wildly different ways—to produce very different products.

Related Content:

Download Issue: Dental Lab Products December 2022

Download Issue: Dental Lab Products December 2022