- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

New Dental Lab Products June 2022

Taking a look at some of the latest dental lab products from around the industry.

On The Cover

Tera Harz TC-85

Tera Harz TC-85 photopolymer material is described as the world’s first direct 3D-printed aligner that features a shape-memory function. Formulated to overcome the current limitations of thermoforming sheet-type aligners, the Tera Harz direct aligner can be 3D printed directly with a 3D printer for more efficient orthodontic treatment and quicker treatments for the patient. Dental professionals can deliver 1-day orthodontic treatment with Tera Harz TC-85DAC, and the dental lab does not need a great expense to set up a manufacturing facility. It can produce a large volume of products with minimized facility investment, reduced manufacturing time, and increased productivity.

What sets this material apart from other resins:

Labs can design Tera Harz direct aligners with 3D software and control the material strength and elasticity. This allows it to be used for various orthodontic treatments while producing optimal treatment results. Because users can design the shape of the direct aligner and control the material strength and elasticity, the orthodontic treatment device is said to perfectly match the characteristics needed to customize for each patient. This product is available in 2 colors: TC-85DAC (clear) and TC-85DAW (white). TC-85DAC is fully transparent and durable, whereas TC-85DAW emphasizes durability and esthetics.

itgraphy.com

On The Cover

Straumann P50+

Designed to meet the productivity needs of dental labs and Dental Service Organizations, the Straumann P50+ delivers user-friendly convenience, with less room for human error. The 3D solution is scalable, automated, and features flexible volume production. It distinguishes itself from conventional 3D printers, with innovative features such as Force Feedback technology, Automatic Separation Module, automatic material refill, intelligent connectivity, and a large build area. It delivers high productivity while maintaining maximum flexibility, enabling more manufacturing freedom and validated processes.

What makes this 3D printing solution innovative:

Patented Force Feedback technology increases print speed, and new intelligent features ensure user friendliness and security. Straumann also offers unrivalled support from a single-source digital solutions supplier. From unboxing to setup, the P50+ is designed to meet your lab needs. Integrated wheels allow freedom and mobility in your lab—move the P50+ where you need it, when you need it. Straumann tests their digital solutions with intelligent connectivity from scan to design and print as 1 system for reliable quality and accuracy.

Straumann.com

On The Cover

Zirkonofen Turbo

Featuring a sintering platform controlled by an intelligent electronic system developed in-house, the new Zirkonofen Turbo and its preset fast sintering programs for each kind of Zirkonzahn zirconia make it possible to sinter smaller zirconia structures in approximately 90 minutes. This cuts processing time by 81% and reduces electric consumption by 73%. Zirconia structures can be milled, sintered, and veneered in as little as 2 hours and 10 minutes. The system monitors the temperature curve of the sintering chamber and controls the platform during the cooling phase. The furnace includes several preset programs that are perfectly matched to each kind of Zirkonzahn zirconia.

What makes this sintering unit worth a look:

Because the preset fast sintering programs perfectly adapt to each material, the smaller and thinner the structure to be sintered, the shorter the required sintering time. With this furnace, 4-unit bridges can now be sintered in approximately 90 minutes. In this furnace, zirconia restorations can be sintered by means of special accessories, such as the sintering trays and the ceramic plate. The sintering chamber can contain up to 3 trays stacked on top of each other, which permit sintering up to 120 zirconia elements in 1 single process. If bridges are sintered with a sintering stabilizer, the ceramic plate must be used.

zirkonzahn.com

Ceramic System

Editor's Choice: This system is said to deliver results comparable to conventionally layered restorations but with significant time savings.

Initial® IQ ONE SQIN

With GC Initial IQ ONE SQIN paintable color-and-form ceramic system, esthetically appealing restorations suitable for the anterior region can easily be achieved. Based on the GC Initial “IQ philosophy,” the system consists of different ceramic materials (Lustre Pastes ONE, SQIN, and Spectrum Stains) that are formulated to perfectly adapt to be used together, assuring an efficient and esthetically convincing finalization of monolithic and buccally reduced restorations. The system’s technique calls for form and fine texture details made in the wet stage (no changes after firing), self-glazing properties for a beautiful glazed finish in 1 single firing; optimal fluorescence level to ensure the look of natural teeth under all light circumstances, and maximum esthetics within a micro-layer.

File Output

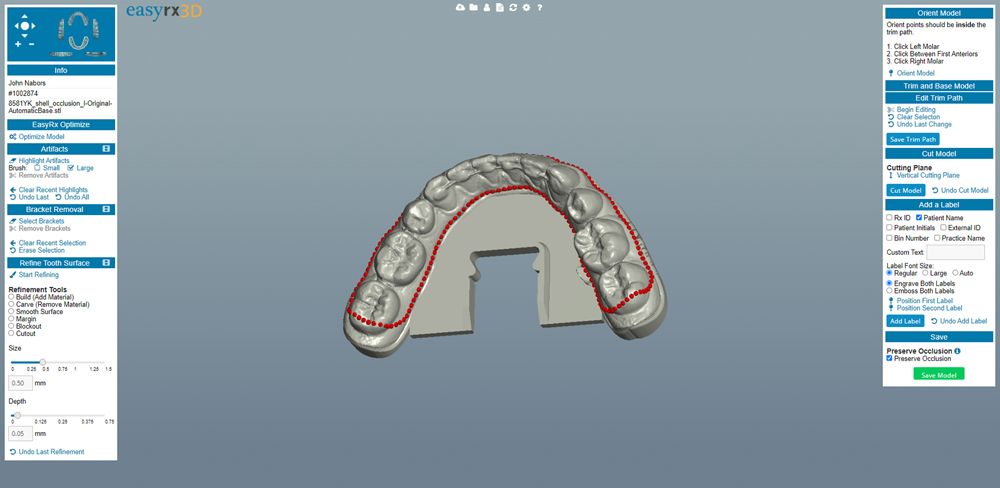

PTS Trim Line File Output

Lab prescription and digital workflow company EasyRx® has announced the addition of PTS Trim Line File Output to 3D Automated Services. After PTS Trim Line generates the based file with the locator base for trimming machines, then these auto-based files and supporting PTS files are attached to EasyRx’s helpful prescription and patient file for viewing and adjustment. Because orthodontists and dentists can manage and design through this tool, the PTS Trim Line File Output expands a practice’s or laboratory’s capabilities to serve patients, according to EasyRx. The 3D Command Center from EasyRx allows users to view the PTS Trim Line and adjust as needed. It is supported by Digital Dental, MAXX, and Ortho-Automation Trimline machines. PTS Trim Line File Output is available for both dental practices and labs.

CAD/CAM Software

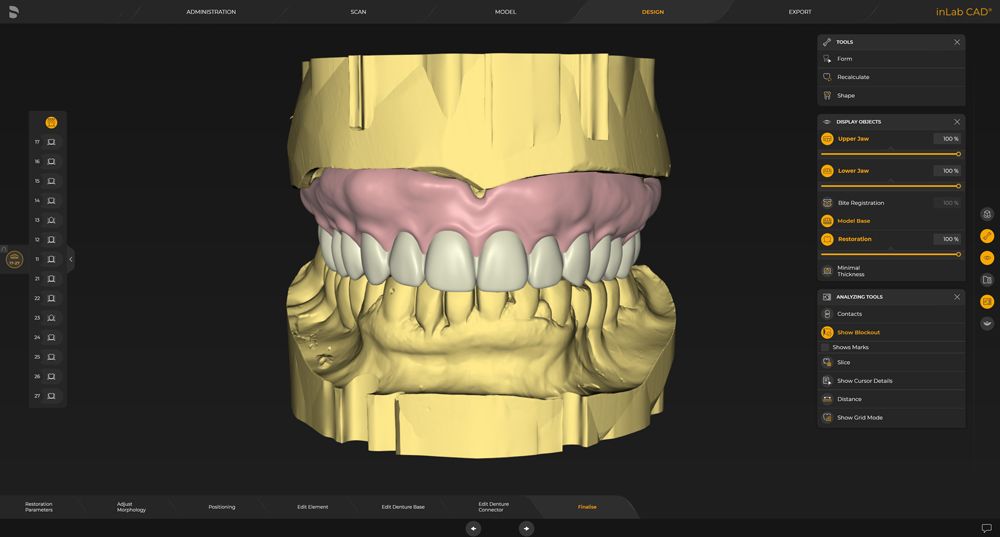

inLab Software 22.0

Designed to make digital manufacturing of dental restorations convenient and flexible, inLab Software 22.0 is available for new and existing Dentsply Sirona customers. Its range of new features includes indication extensions as well as a new, harmonized user interface for a modern look and an easy and seamless transition to other software products in the company’s product line. It follows in the footsteps of the company’s successfully established solution for digitally manufactured full dentures. It offers the extension for full-over-natural dentures (single arch denture), optimizes gingiva designs, and integrates new Digital Genios and Digital Portrait tooth libraries from Dentsply Sirona used in milling and 3D print production.

Dust Shield Bur

Abbott-Robinson™ Chuck Saver Bur

Buffalo Dental Manufacturing Co Inc has introduced its new Abbott-RobinsonChuck Saver Bur, which blocks around 95% of grit from entering the handpiece, according to the company. The Chuck Saver Bur is designed to protect handpieces from dust and premature malfunctions for a longer life span, thereby saving money and time for any volume practice. It will join the Buffalo line of Chuck Saver Bristle Brushes and will be available through preferred dealers.

Download Issue: Dental Lab Products June 2022

Download Issue: Dental Lab Products June 2022