Editor's Choice

exoplan 3.0 Galway has 40 new features, as well as enhancements to more than 60 existing functionalities.

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

A look at some of the latest dental lab products from around the industry.

Zubler’s 3:45 Zirconia is a zirconia-based ceramic that is provided in various shapes, such as round and/or square, for use in the manufacturing of all ceramic crown substructures, including anterior and posterior restorations, full arches, and implant-supported full arches. It is said to offer speed sintering of full arches, including implant-supported arch constructions, in under 4 hours.

Why this zirconia is unique

3:45 Zirconia does not require the use of base or support structures during the sintering process. This is said to save significant amounts of zirconia that can be used for single posterior units or 3-unit bridges. The zirconia comes preshaded (mono). Available shades include A0, B1, A1, and BL1. This product is available in multiple sizes, including 98 mm × 25 mm and 98 mm × 30 mm, allowing the zirconia to accommodate a variety of milling machines.

The MD-500 is a 5-axis milling machine developed specifically for dentistry. The 5-axis servo motor control enables high-speed, high-accuracy, and high-quality machining of prostheses. The unit’s highly accurate milling offers thin margin lines, reducing the operation time required for hand finishing by a lab technician. The C-shaped clamp has an opening that allows the milling tool to directly process the interproximal areas of frontal teeth, which improves esthetics. The original application, md-gear, provides a user-friendly screen to meet the various needs of dental laboratories, including rearranging milling orders and extracting unfinished work.

Why this milling machine stands out

The MD-500 features a single frame base X, Y, and Z axes, providing high rigidity. A combination of spindle with the fixed holder minimizes fluctuation at the drill tip while the linear guides and ball screws enable precise positioning and stable milling. The linear guides and ball screws for the X, Y, and Z axes, as well as the decelerators for the A and B axes, contribute to the reduction of displacement, and as a result, no calibration is needed.

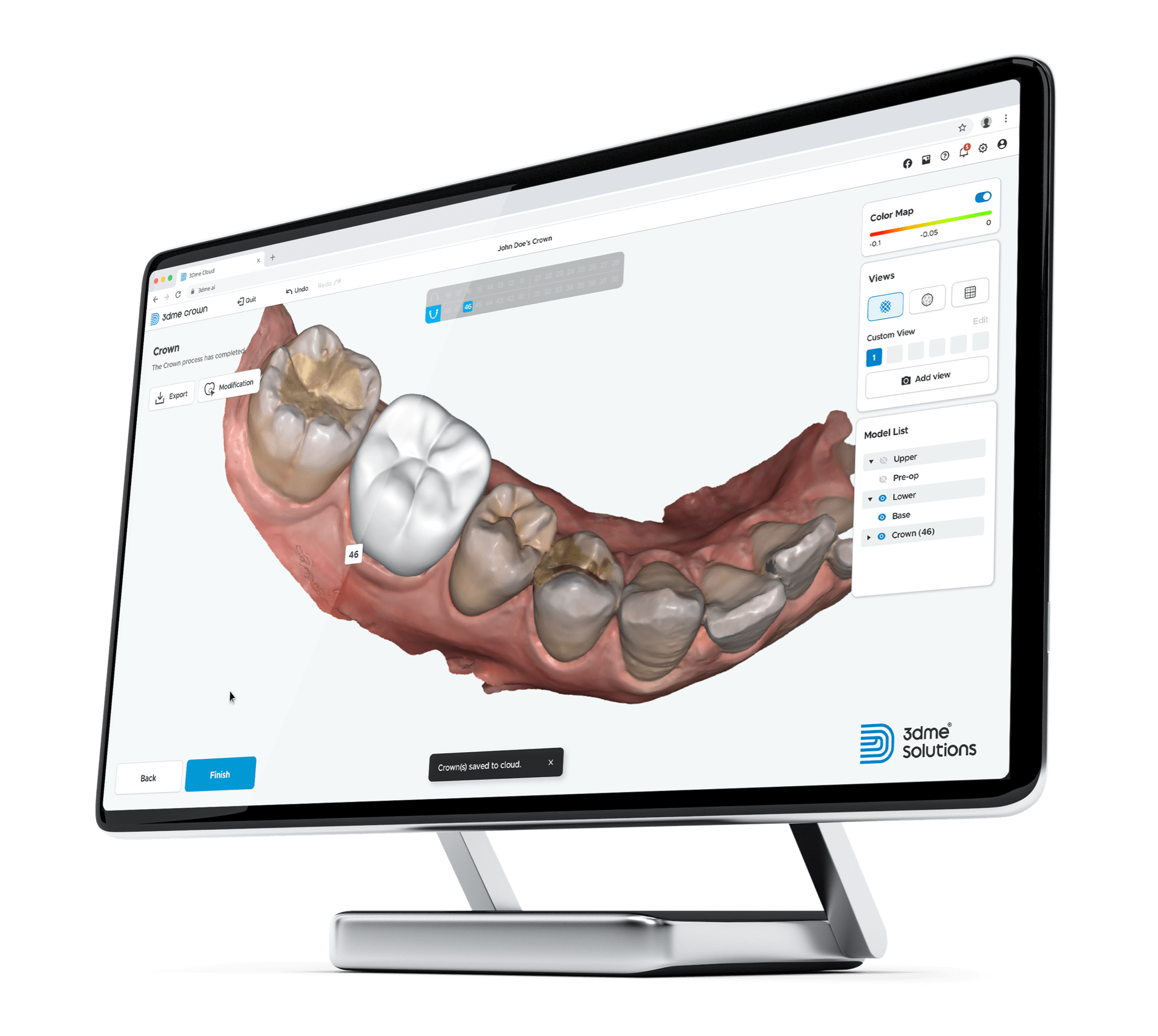

Imagoworks’ 3Dme Crown is an automatic crown design module of the company’s 3Dme Solutions. Based on the patient’s 3D scan data, using artificial intelligence (AI) technology, the crown prosthesis design that is most suitable for the patient’s oral environment is automatically generated in seconds with the solution. The crown design, using the existing dental CAD, is done through dozens of mouse clicks for over 10 to 15 minutes by skilled dentists and dental technicians. However, the process reportedly takes only seconds, with just a few clicks using 3Dme Crown. The crown design can be downloaded in several desired file formats. The 3Dme Crown can be accessed and used from anywhere in the world after member registration.

What sets this software apart

3Dme Crown’s AI technology automatically finds the tooth that requires crown design by examining the dental 3D scan data. At the same time, it automatically identifies the margin line between the tooth and gum of the crown prosthesis to be manufactured and suggests an optimized margin line. It then goes through a process of creating an optimal crown design in a matter of seconds, considering the surrounding and antagonist teeth.

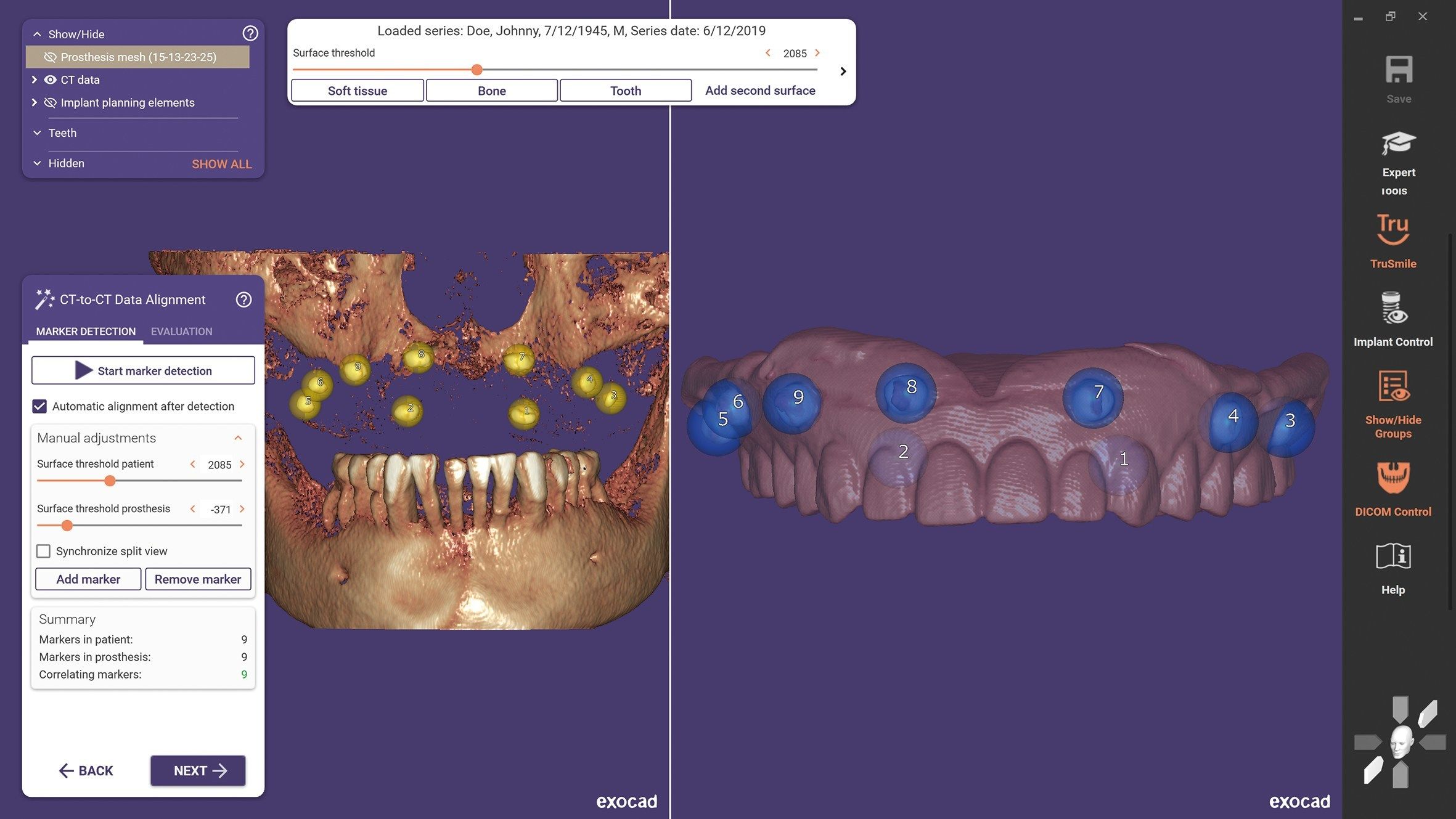

exoplan 3.0 Galway has 40 new features, as well as enhancements to more than 60 existing functionalities.

exoplan 3.0 Galway supports the planning of edentulous cases, including the design of surgical guides. Customized surgical guides can be designed using the Guide Creator software module, then produced in a laboratory, dental practice, or an external production center. Key features of exoplan 3.0 Galway include planning of edentulous cases and design of the respective surgical guides, including necessary tools such as dual scan protocol, anchor pin placement, and fixation guide; surgical and fixation guides that can be freely designed or based on a prosthesis scan; new tools to speed up the entire planning process; improved implant selection dialog; automatic panoramic curve detection; and clearly marked sinus cavity imaging.

The T3 PRO will build on the original T3 Tapered Implant, whereas the Encode Emergence Healing Abutment will work with ZimVie’s 3-in-1 Encode Impression System. The T3 PRO is designed with a hybrid surface and an Osseotite surface on the implant collar, which is superimposed on the grit-blasted implant body. The T3 PRO Tapered Implant has a modernized collar design for placement depth adjustment and self-tapping threads for controlled insertion. The healing abutment is designed for clear intraoral scanning and restoration precision, with a pink color to match most gingiva.

Liquid Crystal (LC) Magna v.2 is a completely reengineered LCD-based printer that is designed to deliver significantly faster print speeds, boost productivity rates, and reduce waste. This product is versatile and is well suited to small batch, on-demand, or full production applications. Thanks to the latest refinements, the LC Magna v.2 offers substantially increased print speeds. For example, 36 custom dental trays (80-mm Z height) at 250-μm layers can now be printed in 1 hour and 13 minutes. Its new hydrophobic platform is designed to further boost productivity and reduce waste. This new Magna is supported by a comprehensive range of high-performance 3D resins and dedicated post-processing units, and is designed to deliver an outstanding value proposition.

Amann Girrbach has announced that it is expanding its Ceramill Full Denture System (FDS) to include validated Ivotion materials from Ivoclar. Ceramill FDS will offer users the ability to mill dental arches and tooth segments with this new expansion and with time and cost efficiency. Ivotion Dent, Ivotion Dent Multi, and Ivotion Base will now all be usable within Ceramill FDS. With Ivotion materials now integrated into this digital workflow, users can use them to mill or fabricate denture bases and combine those bases with prefabricated teeth from other manufacturers. As part of this, Ceramill FDS’ Ceramill Mind Software has been updated to include all components, materials, and stored gap dimensions.

EasyRx Digitize creates a streamlined digital workflow for plaster cases

EasyRx Digitize is an impression-to-digital file conversion service that allows users to convert plaster impressions to digital STL files and automatically attach the scans to EasyRx prescriptions. Plaster impressions are converted to digital files in a few easy steps. Users can simply select EasyRx Digitize when submitting an EasyRx prescription, ship the impressions to EasyRx by using the autogenerated shipping label, and digital files are attached within 48 hours after impressions are received at EasyRx. The case can then be put into production, using the STL files, updating the workflow in EasyRx. This service is a universal system that allows orthodontists and dentists to design, create, manage, and submit their patient’s appliance prescriptions online to any orthodontic or dental laboratory in the world or in-house lab.

Dentsply Sirona has announced its new Lucitone Digital IPN 3D Premium Tooth. The material is fully integrated with the Lucitone Digital Print Denture System and is validated for Carbon M-Series printers, as well as Asiga PRO 4K and MAX UV. This new material is said to use light reflection and refraction to create the kind of texture and translucency necessary for esthetically pleasing denture teeth. This material is suitable for full dentures, implant-supported dentures, and partial dentures, and it boosts digital dental workflows. Lucitone Digital IPN 3D Premium Tooth is available in 16 A-D shades and 2 bleach options.

Designed for dental practices and laboratories, the Quicr Quantum Implant Cementer offers the correct seating and cementing of crowns and abutments, saving time. Quicr Quantum comes in 3 parts—A, B, and C—that are easily assembled. Piece B screws into piece A and the Tibase/Abutment is quickly placed on part A/B. The abutment and crown are then treated and cement is mixed and placed on the Tibase/Abutment. The crown can then be placed on the abutment and excess cement is easily cleaned off. Piece C is screwed on to hold the crown in place.

KATANA Zirconia YML is a multilayered disc with a well-balanced combination of color, translucency, and flexural strength gradation. With proprietary multilayered technology, this latest development has been realized by matching 3 raw materials with different yttria contents. A pressing and presintering technique allows users to realize restorations of up to 3-unit bridges without any compromise in terms of esthetics or mechanical properties, using the 90-minute high-speed sintering process. From veneers up to full-arch restorations, in each case, users may choose a monolithic, cut-back, or framework design with the appropriate fabrication procedure, depending on individual needs.

Download Issue: Dental Lab Products August 2022

Download Issue: Dental Lab Products August 2022