- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

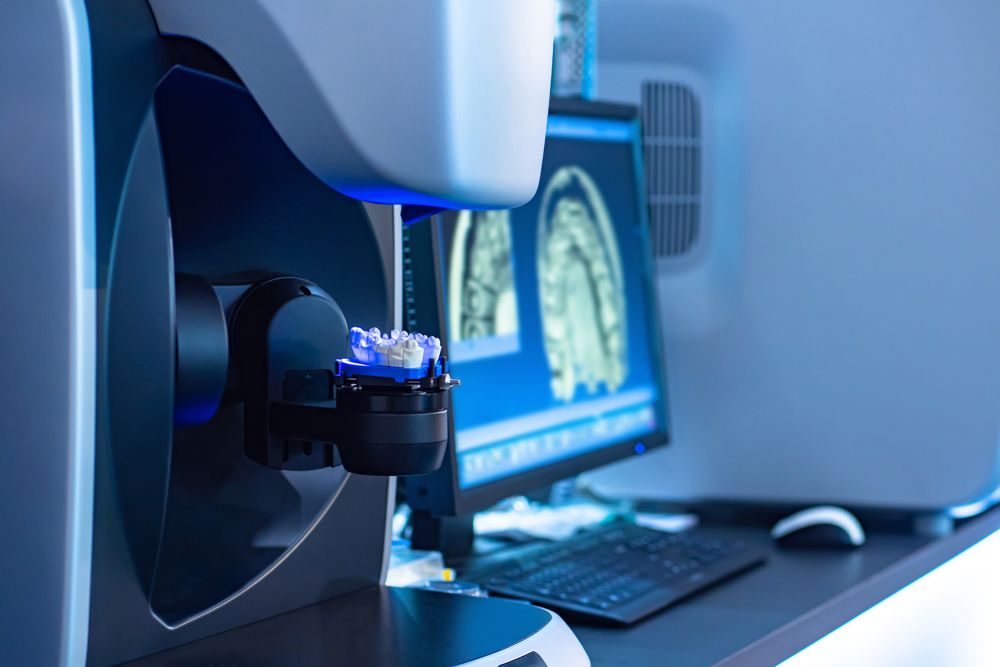

More Than Just Run-of-the-Mill Technology

Here’s a look at some of the dental milling machines that are available.

There are many options, features, and specifications to consider when selecting the best milling unit for your lab.

It’s a big decision and one that depends on what type of materials you use, how much you have allocated to spend, and how your particular dental lab operates on a day-to-day basis.

Today’s milling machine options are plentiful, and the systems are designed for all types of dental labs and a wide array of applications. Many of today’s milling machines are compact, quick, and versatile. They can be compatible with a variety of materials, CAD/CAM software options, and technologies that enable flexibility, efficiency, and time and money savings.

From dry or wet milling to chairside or high-tech laboratory mills, all of these options can make purchasing a dental milling machine seem overwhelming. Before making this big decision, be aware of your overall budget, the specifications required to allow you to get what you expect from the technology, and which materials you prefer to use with your milling system.

Ceramill Matik

The Ceramill Matikfull-service unit combines 3 machines in 1. Separate from the processing station, the system also performs the functions of a fully automated stock management system and a machine cleaning device. The support in loading, cleaning, and material management saves time during laboratory routines. Additional software makes optimum use of materials and tools. Another highlight is the newly designed 5X machining station. It offers innovative processing methods such as the patented carving mode, thrilling (production of 1-piece abutments), and speed milling of acrylic materials, as well as the maximum material range.

PrograMill® One®

Described as the smallest 5-axis, smart milling machine, the PrograMill One combines high precision with industrial production quality. The self-contained system does not require any separate filtration or suction units. The wireless unit can be operated via an app from a tablet or smartphone, and an LED light ring informs users about the current processing status. A camera within the unit captures all data on material and tool usage. The infeed remains consistent, and the tool never leaves the workpiece, which enables short machining times while reducing tool wear. The result is an optimal surface quality and excellent fit of the restorations.

Milling Unit M1

The Milling Unit M1 machine compact line is available in several models in order to meet the different requirements of digital dentistry. The complete Milling Unit M1 line is particularly compact (18.77 × 27.28 × 24.13 in) and has an extremely short milling time, thanks to its fast engines. It can be combined with the Zirkonzahn Scanner S600 ARTI and the user-friendly Zirkonzahn software. Other units in the M1 Line include the M1 Abutment Milling Unit, M1 Soft Milling Unit, M1 Wet Milling Unit, and M1 Wet Heavy Metal Milling Unit.

MAXX DS Series

The DS Series from Maxx Digm has been specially engineered for machining dental materials such as zirconia, PMMA, wax, glass ceramics, and resin composites. Extremely accurate and high-precision results have been repeatedly validated through third-party production sites and testing facilities. The DS200-4WA model is a 4-axis desktop milling machine designed for Ti premilled blanks. It is small and compact yet provides fast and accurate milling.

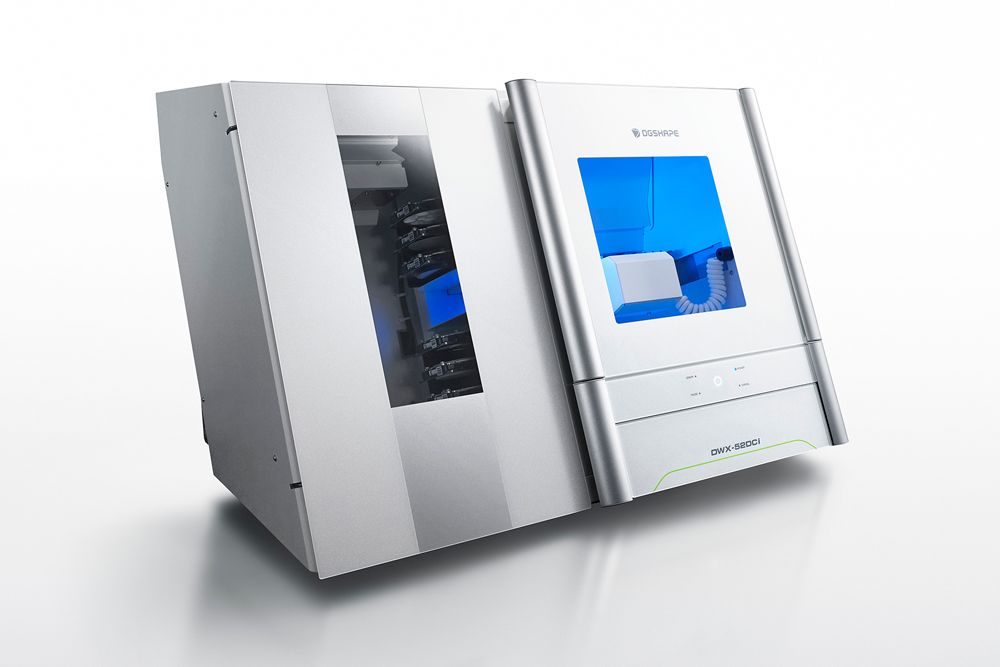

DWX-52DCi

The DWX-52DCi dental milling machine with automatic disc changer (ADC) is designed to expand lab production and profit. Its 6-slot ADC, 15-station automatic tool changer, and other automated features give users of all skill levels an exceptionally powerful, efficient, and affordable dental restoration solution. With the ADC, users load the 6 material adapters with different shades of zirconia or any combination of material discs. Assign the adapters with milling jobs and the automatic disc changer does the rest. The adapter system enables multidevice adapter integration.

inLab MC X5

The inLab MC X5 was designed as a universal 5-axis production unit to meet dental laboratory requirements for cost-efficient production. Dentsply Sirona offers independence in terms of material and indications as well as the processing of external CAD data. The inLab MC X5 is a universal production unit for processing zirconia, polymers, composites, wax and sintering metal, and glass and hybrid ceramics. Choose among Dentsply Sirona’s own brand of CAD/CAM materials and a variety of CAD/CAM material partners for high-quality materials to which the unit processes were specifically adapted.

Alien R5

The Alien R5 highly automated milling and grinding machine brings revolutionary approaches to the lab along with a 10-fold blank changer for wet and dry machining. Its minimal footprint combines precision with maximum stability and can handle any material. The R5 effortlessly switches between wet and dry machining. In addition to ionizers and active workspace ventilation, the machine offers an intelligent drying function.

Z4

Developed for same-day applications, the Z4 features intuitive, easy-to-use operating controls that conceal a high-precision milling and grinding machine. The digital workflow makes it happen, and patients benefit from more pleasant treatments with first-class restorations in just 1 session. The Z4 is designed to produce high-quality restorations with maximum independence. The number of machinable block materials constantly increases as does the number of scanners and CAD software packages that are validated with the Z4. From the intraoral scanner to the milling machine, users work with a single interface.

DM5XT Crystal Ultra™/Trilor Wet Mill

This hybrid production mill is built for heavy-duty 5-axis milling. The DM5XT features a 400 B axis tilt and the high-torque, 2.7 kw Super Spindle, which enables the DM5XT to power through hard-to-mill hybrid materials such as Crystal Ultra™ , Trilor, and double cross-linked polymers. Digital Dental Mills are built to be the strongest, most accurate, and most durable dental milling machines in the industry. They are not desktop mills. Built out of solid 2-in-thick aluminum billet, these are industry-grade production machines. Their rigidity is the key to consistent, accurate milling over many years.

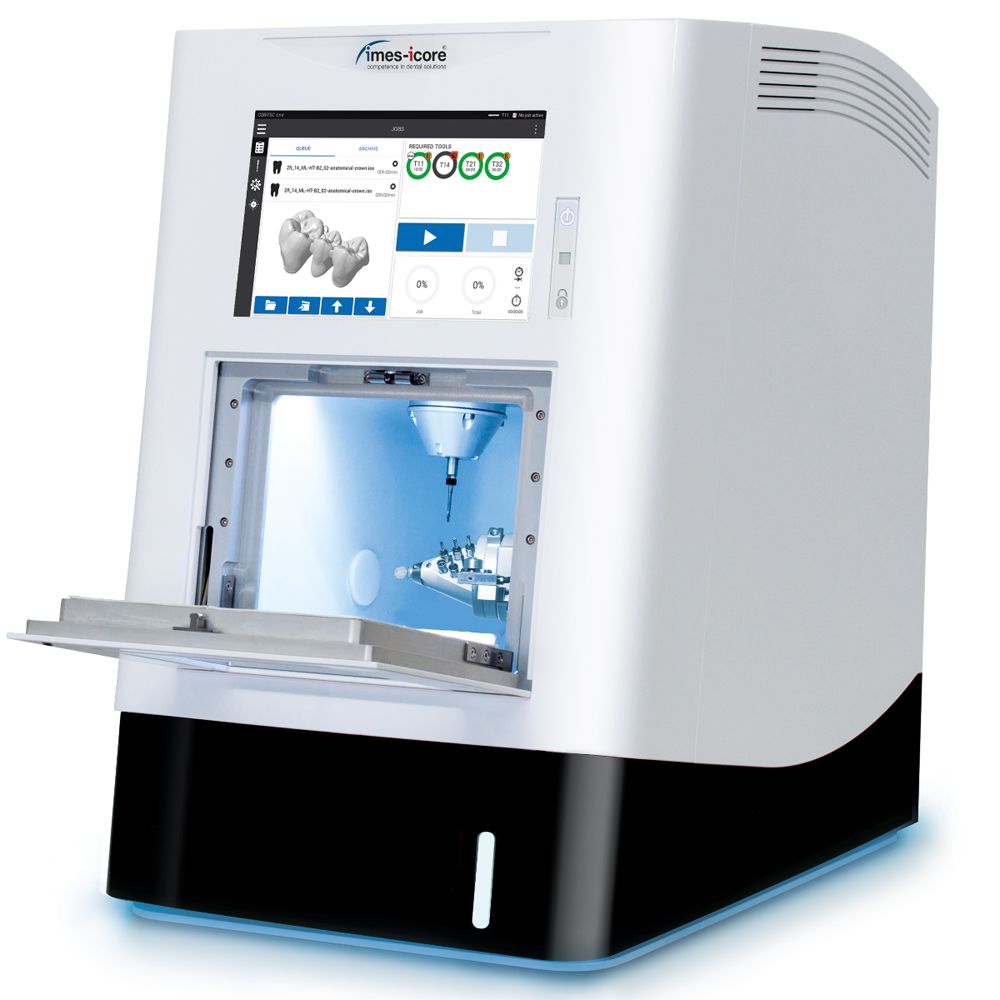

CORiTEC one®

The CORiTEC one machine is ideal for processing all common designed CAD/CAM blocks. With its stable axis kinematics, the machine is capable of milling prefabricated abutments. The high-quality cast aluminum construction ensures maximum stability with a minimum footprint. An integrated, powerful computer, and high-definition touch screen display support a comfortable and ergonomic operation. A single block holder with 6 tool positions and smart tool replacement function guarantees an economical, safe, and fast machining process with the highest quality. It is ideally suited for dental offices, practice laboratories, and clinics in combination with all open scanners.

X-Mill 600 5-Axis

Featuring an intelligent touch screen and 1-button processing, the X-Mill 600 5-Axis is an all-in-one wet milling system. With a small size and comprehensive function, the high-quality milling unit delivers high precision and high-speed workability. The versatile milling unit can process dental crowns, bridges, abutments, rod clamps, planting bridges, and brackets. The X-Mill 600 5-Axis features automatic bur changing with a 12-bur capacity. It works with CoCr/NEM, titanium, PMMA, wax, glass ceramics, and hybrid ceramics.

DC1™

The DC1 allows laboratories of all sizes to be competitive and offers dental technicians a smooth entry into CAD/CAM technology. The DC1 milling system was developed by engineers at Dental Concept Systems for the purpose of introducing a milling machine to the compact class that was versatile yet fully capable of milling CoCr with the same precision as the company’s larger units. Equipped with a large spindle and motor, the system allows the efficient milling of metals with smooth finishes of the type normally reserved for larger machines. The desktop unit can safely drill and finish high-quality geometries for abutments and has an automatic machine calibration feature.

Planmeca PlanMill® 50 S

The 5-axis Planmeca PlanMill 50 S unit is a powerful choice for wet and dry milling discs and blocks. Equipped with a high-speed spindle and automatic changer for 12 tools, Planmeca PlanMill 50 S is capable of both wet and dry milling of indications such as dental restorations, bite splints, and dental models. Restorations designed with the Planmeca PlanCAD™ Premium software can be directly launched to Planmeca PlanCAM™, the Planmeca PlanMill 50 S unit’s easy-to-use software that supports all open STL files.

Axsys Versamill 5X400

Constructed using the technology found in full-frame CNC industrial machines, the Versamill 5X400 is designed to perform reliably with high precision for the long term. This purpose-built, open-source 5-axis mill provides users with maximum flexibility and versatility. It can accept input from popular dental design programs and process virtually any dental milling materials, including wax, zirconia, acrylic, composites, glass ceramics, and more. Coupled with the undercut machining capability of full 5-axis control, it provides superior surface finishes, faster cycle times, and greater tool life.

TRÜMILL X350 Series

Described as the automated all-in-one solution, the TRÜMILL X350 series milling machines feature up to 30° or greater axis adjustment for a 5-axis machining system, increased efficiency, water-cooled spindle, zero-point clamping system, polymer concrete base, and a stainless-steel blank holder for high stability and reduction of vibrations. The TRÜMILL X350 provides up to 20% faster machining due to high-resolution dynamic servo motors and 24-hour production operation.

Craft 5X

A truly all-in-one 5-axis dental mill, the CRAFT 5X is designed to save space without compromising milling quality or flexibility. The system mills on the X, Y, and Z axes, and the blocks or discs being milled can rotate 3600 in either direction. It can operate in both wet and dry modes, allowing a wide range of materials to be milled, and it features a powerful closed-loop motor system. The system’s sturdy construction reduces vibration, and the Jäger spindle can reach up to 100,000 RPM with a maximum power of 700 W to provide the system with both power and accuracy. The system can be controlled via an onboard computer and touch screen control with an intuitive interface.

Download Issue: Dental Lab Products August 2021

Download Issue: Dental Lab Products August 2021