How To Make Digital Processing the Key to Innovation

Technology is creating a demand for simpler processing, faster fabrication, better strength and esthetics, and ultimately more innovative products.

A new era of CAD and digital processing has changed the dental restorative landscape forever. This evolution will have far-reaching effects on the industry and lab owners and technicians alike must stay vigilant to navigate these uncharted waters.

Long gone are the days of asking, “What should we adopt?” The modern question has now evolved into, “How should we adapt?” Unfortunately, this question does not dig deep enough to truly uncover the potential danger as well as amazing opportunities that lie within technology itself.

In the past, suppliers introduced new restorative materials to clinicians not only through marketing, but also through dental laboratory partners. By effectively utilizing dental technicians and their clinician relationships, these corporations were able to drive new and innovative products to the clinical customer base. Through this strategy these suppliers were able to create internationally recognized brands like Ivoclar Vivadent’s IPS e.max, Nobel Biocare’s Procera Alumina and 3M’s LAVA Zirconia.

Today, these companies not only continue to develop new materials but now also supply the equipment and software needed to produce these prosthetics. The progressive dental laboratory now has the same ability to design proprietary products that was previously only available to large corporations.

Creating prosthetics through digital design has now become an industry standard and having the ability to creatively manage the data is the way of the future!

Only a decade ago a wax-knife or porcelain brush was seen as the ultimate creative instrument. Today, digital design has taken over as the artistic instrument of choice and the computer has replaced most of the diagnostic tools historically used by technicians.

The technician of the future’s success depends on their ability to create new products from data and understand the capabilities of the powerful software programs at their disposal.

Case Study – Digital Prototyping

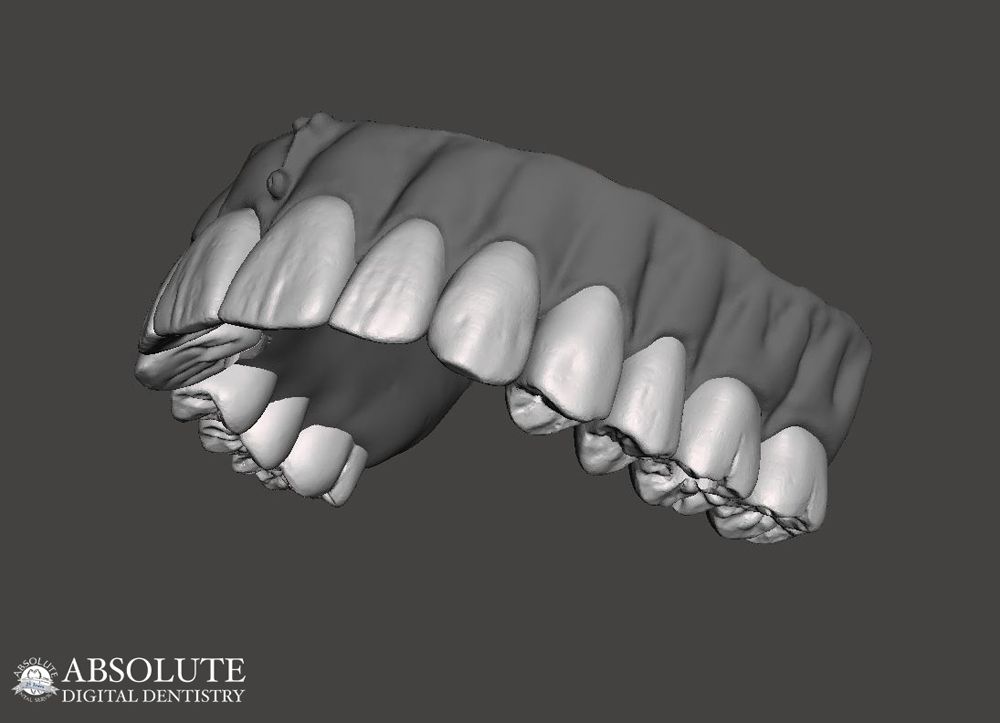

Digital prototyping is arguably the biggest advancement in the processing workflow of a full-arch hybrid or more complex restorative case. The advantage of prototyping (Figure 1) is that the suggested digital diagnostic can be accurately transferred to the patient’s mouth for approval. Because of this technology, the patient can wear a trial prosthesis. This appliance is archived with a digital design file that will be used for the final prosthetic processing. After required adjustments (reductive and/or additive) are made directly to the prototype intraorally, the device is redigitized and ultimately used for the final prosthetic design (Figure 2).

The Problem

Hand processing and reductive fabrication

To produce an effective prototype, these temporary prosthetics must be lifelike. Analog fabrication of these devices requires high artistic ability and large amounts of hands-on skill, making this a labor-intensive interim procedure. With labor shortages in the industry predicted to worsen, technology must be utilized to reduce the amount of hand processing required to produce these devices.

The culprits causing most of this arduous hand processing can be attributed to the reductive fabrication process. Gingival contouring further complicates the process, especially in FP2 or FP3 style restorations (Figure 3).

Software Design Limitations

Unfortunately, off-the-shelf design software, such as 3Shape or exocad, even though pioneers in the dental design arena, does not yet offer adequate design freedom to process these types of complex custom prosthetics. It is therefore important to find innovative solutions with workarounds and software switching. STL file management allows for very advanced design processes, giving today’s technician the ability to create prosthetics not currently seen as possible.

The Solution

Innovative materials and additive fabrication

With the recent launch of products such as FlexceraSmile and BEGO Varseo, tooth structures can now be printed instead of milled. Ultimately, printing a tooth structure is significantly faster than milling. A full arch unit requires, on average, 3.5 to 4 hours of milling time, whereas printing the same arch requires 2 to 2.5 hours. Although printing times are on average 40% faster than milling, the true advantage of printing is only seen when multiple arches are processed at the same time. Utilizing a printer like the EnvisionTEC or Formlabs Form 3B, the operator can nest 8 to 12 full arches on a printing plate, and processing time for a fully nested tray, is on average 4.5 to 5 hours. This makes additive technology scalable and a clear favorite over reductive processing.

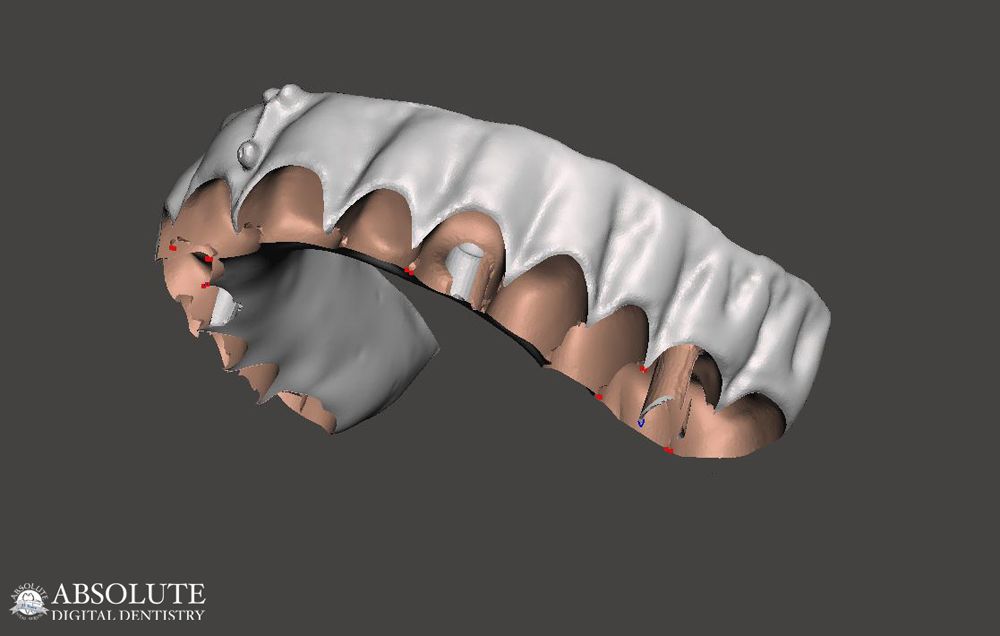

The biggest benefit of additive technology is the accuracy with which the structures are produced. Final processing of a milled PMMA full arch requires on average 45 to 60 minutes of skilled hand processing, while final processing a printed arch only requires 15 to 20 minutes. Because the structure is printed at 50-micron accuracy, additive technology has no limitations when printing into an undercut is needed. Therefore, printed structures produced with addictive technology require only minimal hand finishing and, in many cases, can be polished without further contouring (Figure 4).

STL File Manipulation and Software Integration

The prototype design (Figure 5) was processed using the 3Shape crown and bridge module. In the order form, the first file was set up as a full upper restoration with an additional bridge in the posterior. This split design allowed our Absolute Digital Team (absolutedentallab.com) to select 2 different tooth libraries within 3Shape. Once designed, the STL files were imported into a secondary software to allow for intaglio fitting surface cut-out (Figure 6). This ultimately left the team with 2 STL files ready for printing. The first STL file represents the tooth structure (Figure 7) and the second file represents the base with intaglio seating surfaces.

Additive Materials

The dental industry is starting to see exponential improvements in additive material development, and many of these new world options are now cleared for long-term intraoral use. As with all product development, these polymer-based options will only become more functional and even stronger with time. One inherent material property of polymer-glass is the material’s ability to re-create lifelike esthetics without the need for external staining.

The prototype base (Figure 8) is now printed with a denture base polymer like Flexcera Base Resin on an EnvisionTEC printing platform or Lucitone 3D Denture Base Resin printed on a Carbon DLP platform.

These base materials are extremely strong, and with a Flexural Modulus of over 2100 J/m² at room temperature and over 3200 J/m² at body temperature, these materials are leading the way into a very exciting future.

Technology is driven by need and need is created by a demand for simpler processing, faster fabrication, better strength and esthetics, and ultimately, more innovative products.

The future is about innovation and dental technicians of the future will be defined by their inventions. Let’s be innovators.

ACKNOWLEDGMENTS

The author would like to acknowledge the contributions of: Mark Ludlow, DMD and Jeffrey Ganeles, DMD, restorative and surgical pictures. Digital design processes and software management by Absolute digital team, Drew VanAarde and Steve Lombardi. Technical artistry by Absolutes Signature ART team, in Durham, North Carolina, under the leadership of Jack Marrano.

Download Issue: Dental Lab Products December 2021

Download Issue: Dental Lab Products December 2021