- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

DPR Top 100: The Top 10 Technology Products of 2023

2023 marked another year of great innovation in the dental industry, allowing clinicians to serve patients better than ever before. From dental 3D printers and 3D printing resins to intraoral scanners, milling machines, and more, the innovations of 2023 helped clinicians dive deeper into digital dentistry, boosting efficiency, saving money, and improving quality of care. Here are the top 10 new dental technologies of 2023.

Image Credit: © SprintRay

// 3D Print Resins

High-Impact Resins

High Impact Denture Base is a ceramic-infused denture material indicated for 3D manufacturing and repair of full and partial dentures and baseplates. Used in tandem with High Impact Denture Teeth, these denture resins are designed to deliver strong mechanical properties for durable dentures. It is the first ceramic-infused 3D printing material, formulated using SprintRay’s proprietary NanoFusion™ chemistry. This novel ceramic composition reportedly achieves its strength by forming dense polymer chains. The new High Impact resins are also fully integrated with the SprintRay 3D printing ecosystem, enabling full denture prints in less than 2 hours.

Image Credit: © DEXIS

// Intraoral Scanner

IS 3800

Described as highly ergonomic and weighing just 190 g without the cable, the DEXIS IS 3800 wired scanner is one of the lightest intraoral scanners available. It complements the company’s IS 3800 W wireless scanner, which weighs only 240 g and is considered the lightest wireless intraoral scanner in the industry. Thanks to its compact and ergonomic design, the IS 3800 offers clinicians optimal ergonomics and a high-speed scanning experience. The scanner is powered by IS ScanFlow software, which redefines and simplifies how you scan, provide diagnoses to, and communicate with your patients. With control of functionality right on the handpiece, including scanning modes, users spend less time switching back and forth between the screen and their patient. With its USB Type-C connection, the IS 3800 derives its power directly from the computer without the need for additional power cables.

Image Credit: © Roland DGA

// Mill

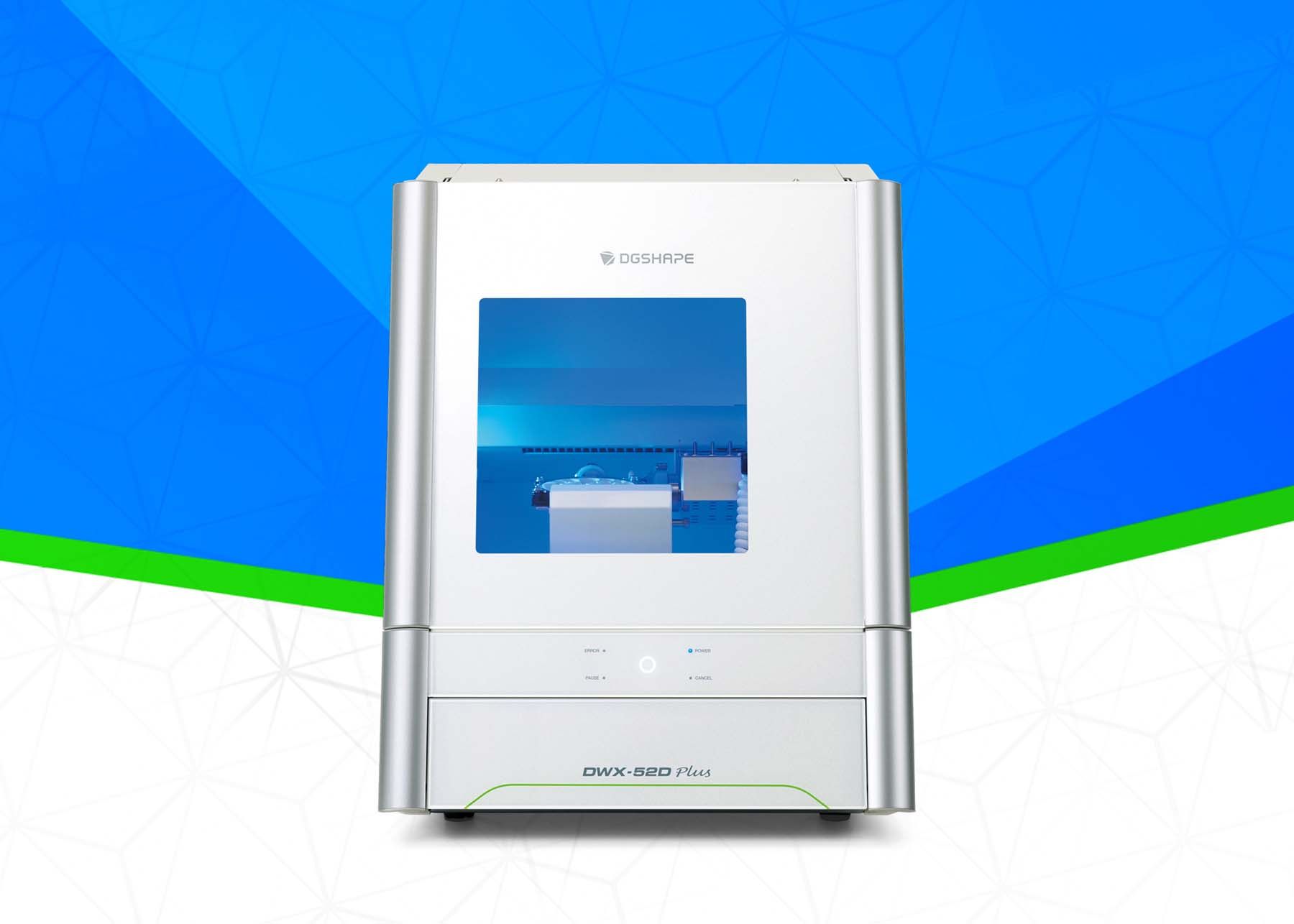

DWX-52D

The DWX-52D is a 5-axis dry milling machine that features an included disc adapter rack, an optional C-Clamp accessory, a 15-station automatic tool changer (ATC), a newly engineered spindle, and the included VPanel software. The disc adapter rack and optional C-Clamp accessory are said to offer more efficient material storage and the ATC offers users the specific combination and tool setup they need for manufacturing. VPanel software connects any DWX Series devices, enabling users to operate mills simultaneously. It also contains Intelligent Tool Control that will automatically replace tools when they have reached life expectancy. Users will be offered free access to DGSHAPE CLOUD performance visualization software.

.jpg?fit=crop&auto=format)

Image Credit: © Glidewell

// 3D Printer

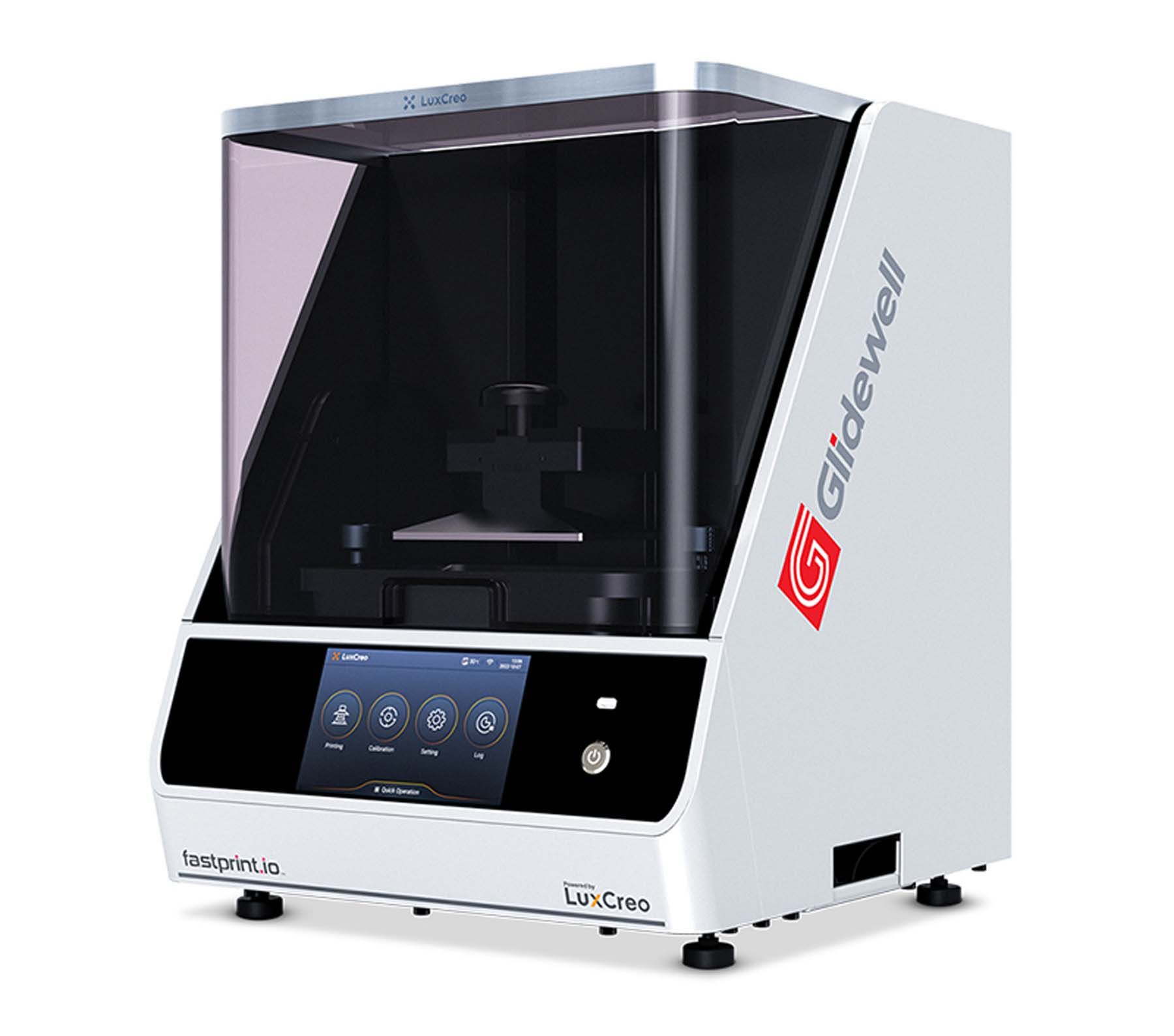

Fastprint.io™ 3D Printing Solution

Glidewell has partnered with 3D printing company LuxCreo to launch its newest solution, the fastprint.io 3D Printing Solution. LuxCreo’s fully integrated solutions comprising cloud-connected 3D printers, artificial intelligence–enabled software, and materials will now work in tandem with the glidewell.io™ In-Office Solution. This new printing solution combines LuxCreo and the glidewell.io In-Office Solution and is designedto offer clinicians an efficient and effective 3D printing solution. A variety of different restorations and appliances can be created using the fastprint.io solution, including models, nightguards, and with recent FDA Class II 510(k) clearance, same-day clear aligners. To boost efficiency, the fastprint.io 3D print solution enables clinicians to directly print clear appliances with LuxCreo Digital Polishing™.

Image Credit: © DentiMax

// X-ray Sensor

Open Sensor by DentiMax

Dentimax’s new Open Sensor is designed to work with major imaging software applications. The Open Sensor is said to offer high-quality x-rays while still maintaining a low cost that makes it accessible to every dental professional. Dental professionals can add this to the office to enhance their digital imaging capabilities while boosting workflows. The sensor is distributed through the Open Sensor Club, which is a subscription club that allows for a $99 per month/sensor payment with a 1-time $499 sensor sign-up fee. As part of this subscription, installation, training, tech support, a lifetime warranty, and accident forgiveness will all be provided for Open Sensor subscribers.

Image Credit: © Planmeca

// Mill

Planmeca PlanMill® 60 S

Planmeca’s new milling unit, the Planmeca PlanMill® 60 S for dental labs, is a 5-axis milling unit that offers wet and dry processing, according to the manufacturer. It is indicated for the processing of discs, blocks, and prefabricated implant abutments, and is designed to offer broader capabilities than the standard chairside mill. Zirconium dioxide, glass ceramics, composites, polymethyl methacrylate, and wax are among the materials that can be processed. PlanMill 60 S contains a half-open blank holder for restorations in the anterior area and touts a clamping holder for quick changes. It is used in conjunction with Planmeca PlanCAM™ software for a full milling workflow for dental labs.

Image Credit: © Formlabs

// 3D Printing

Automation Ecosystem

The new Automation Ecosystem boosts productivity through its Form Auto, Fleet Control, and High Volume Resin System. These aspects reduce idle printer time and boost production, according to Formlabs. Users can expand to a full fleet of dental 3D printers, with the Automation Ecosystem touting increases in productivity while saving on labor, lowering cost per part, and reducing package waste. Form Auto enables automatic part removal, removing finished parts from Build Platform 2 using Quick Release Technology. The next print can start right away, allowing for boosted productivity and no downtime. Prints can be queued for optimal time efficiency. Fleet Control optimizes fleet productivity through its centralized queue management and automatic printer assignment. This fleet management protocol works with Form 3B+ and Form 3BL printer fleets. The high-volume resin system increases resin capacity to 5 liters. This is said to be 5 times the standard cartridge size, which allows users to create more parts without having to replace the cartridge as often.

Image Credit: © Panda Scanner

// Intraoral Scanner

PANDA P3

Panda Scanner’s latest intraoral scanner, the PANDA P3, is designed to create maximum value for every user. It is much smaller and easy to operate, and features include artificial intelligence technology; 3 different tips to meet more demands of different applications; a clear margin line (full high-definition color) for high accuracy; fast scanning speed; and powder-free and true color scans. According to Panda, full arch scanning can be completed in 1 to 2 minutes with the lightweight handpiece (228 g) and it delivers precise, accurate results; accurate anatomical features; 3D high-definition color; and visual communication for an easy treatment experience.

Image Credit: © vhf Inc

// Mill

E5

The E5 is a dry milling machine for discs that masters complex indications with the highest precision, thanks to its 5 axes. The E5 is said to be easy to operate, service, and handle. It does not require any compressed air and is described as cost-effective and sustainable. The patent-pending AIRTOOL generates airflow with its turbine blades, which keeps the workpiece free of chips during milling. The low weight of the E5 (43 kg) was achieved by applying the finite element method. Its design ensures reliable operation at all times and also ensures that almost all materials milled dry can be processed—from plastics to composites, and zirconia to cobalt/chrome sintered metals.

Image Credit: © Ori Dental

// Intraoral Scanner

Ori Intraoral Scanner

Ori Dental’s new Ori Intraoral Scanner has a variety of different features to appeal to dental professionals looking to expand their scanning capabilities at an affordable rate. It is designed to guarantee higher accuracy, differentiating between soft and hard tissue, and is said to be the only dental scanner made in the United States. Described as a modern alternative to traditional dental impressions that delivers a faster, easier, and more accurate solution, the scanner provides a better patient experience overall. It is constructed with aerospace-grade aluminum, and touts high strength and longevity. With an open software system, users can send their scans to their preferred laboratory, and these can be made with the product’s less-than-5-minute scan time. The scanner has no operating fee, allowing clinicians to eliminate the concern over adding monthly fees. The lightweight, comfortable scanner is said to eliminate hand, arm, and shoulder fatigue in dental professionals.

Download Issue: Dental Products Report January 2024

Download Issue: Dental Products Report January 2024