- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

A Range of Technologies Sparks Interest From Dental Labs

Unpacking the results of the Dental Lab Products® 2021 Technology Survey

Technology continues to advance offering new approaches to familiar challenges, and new levels of accuracy and efficiency for everyday processes. As new systems and materials roll out, they create new workflows and reshape what a dental lab can look like. Some labs were early adopters of CAD/CAM technologies and move every case through a digital workflow involving powerful software applications, precise scanners, robust milling systems, and versatile 3D printers. Other labs are more reserved in their approach to technological innovations and choose to take advantage of numerous digital outsource partners rather than investing in the technology itself.

Regardless of how quickly or completely a dental lab has adopted new high-tech approaches, the industry looks very different than it once did, and every lab is feeling the effect of these changes. The Dental Lab Products® 2021 Technology Survey asked technicians and lab owners to share their opinions on what technologies they use, which ones they plan to use in the future, and how they evaluate new technologies to determine which will best fit their specific lab. Read on to see the results and learn how you compare with your colleagues when it comes to dental lab technology.

[ Technology Profiles ]

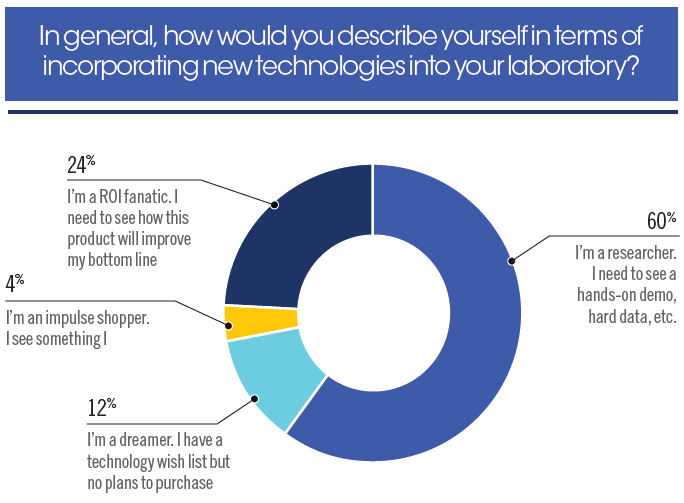

When it comes to evaluating new technology prior to making an investment, it’s clear that lab professionals take a pragmatic approach. Sure, new machines might be exciting to think about and fun to investigate, but most technicians and lab owners need to see more than a flashy pitch before they open their wallets. Just 4% describe themselves as impulse shoppers when it comes to new technologies, whereas 60% look for data and a demonstration before being convinced an innovation is a fit for their lab. A further 24% are focused on making a sound business decision and look for a clear path to ROI when examining new high-tech options.

[ Money Making Tech ]

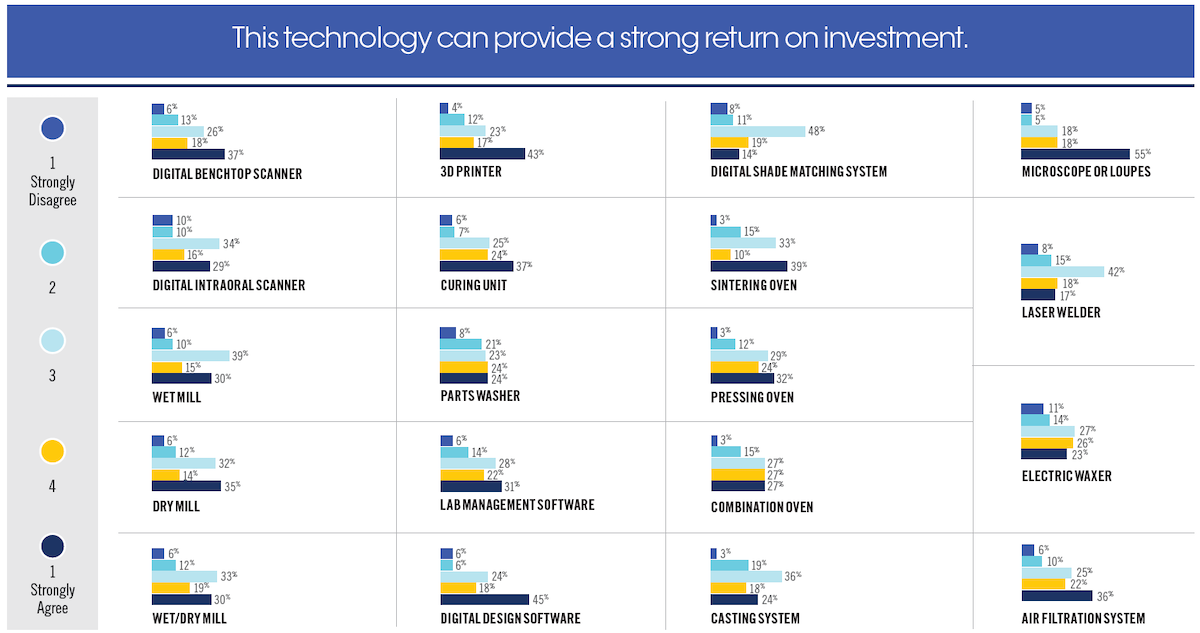

Making sure a technology investment will provide a sound return on a lab’s investment is a priority for every business, and for the most part, dental lab professionals see strong potential for returns from investing in almost any type of lab technology. Although more than 10% of lab professionals say intraoral scanners and electric waxers do not have the potential to provide a solid return on investment (ROI), those were the only 2 categories where the ROI potential was questioned even that much. In fact, just 5 tech categories had less than 25% of lab professionals saying they strongly agree that the technology can provide a strong ROI. Those categories—electric waxers, laser welders, casting systems, digital shade matching systems, and parts washers—were still seen as providing a strong ROI by at least 14% of lab professionals. The top ROI providing technologies according to the survey are magnification systems, CAD software, 3D printers, and curing units.

[ Attractive Technologies ]

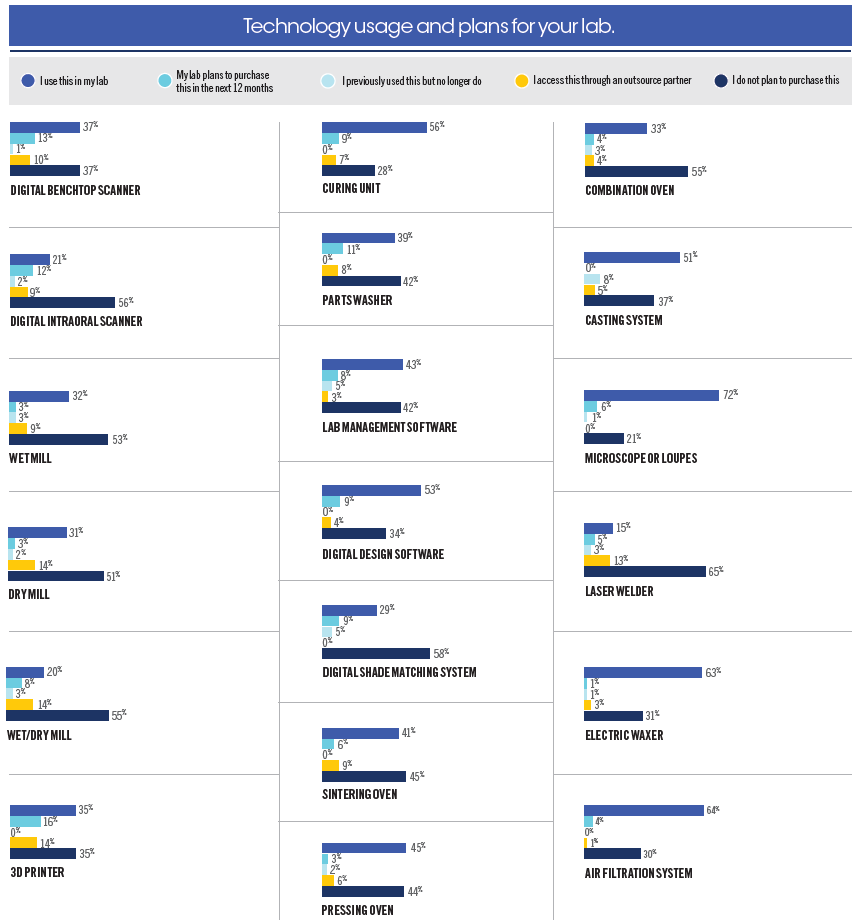

When it comes to which technologies are most widely used, as well as those in demand via outsource partners, or planned for future investment, there is no one approach dominating the industry. Instead there is plenty of balance between labs that have gone all in on in-house digital workflows, and those investing in the updated technologies powering enhanced traditional lab processes. Magnification is clearly important as it was the only category in use by more than 70% of labs, whereas air filtration and electric waxing systems were used by 64% and 63% of labs, respectively. Most CAD/CAM technologies were in use in 20% to 35% of labs, but although the types of scanners, mills, and printers differed, 53% of labs said they do use digital design software. Those digital technologies do show up among planned investments, as 16% of labs say they plan to add a 3D printer in the next 12 months. The survey shows that when a lab invests in a technology they put it to work, as no category of technology was tried and abandoned by even 10% of labs. In fact, the only technology that more than 5% of labs say they used to use and no longer do is casting systems, which have been used and set aside by 8% of labs. When it comes to outsourcing, digital technologies were most commonly accessed via an outsource partner, but no one technology was outsourced by more than 15% of labs.

[ Tech that Gets Noticed ]

When it comes to technologies that clients will notice, the same set of technologies is leading the way. 3D printers are seen as the most impressive while also having the lowest percentage of lab professionals saying these additive manufacturing systems are not impressive. Other technologies that are seen as impressive to clients include CAD software and magnification solutions.

[ Tech With Value ]

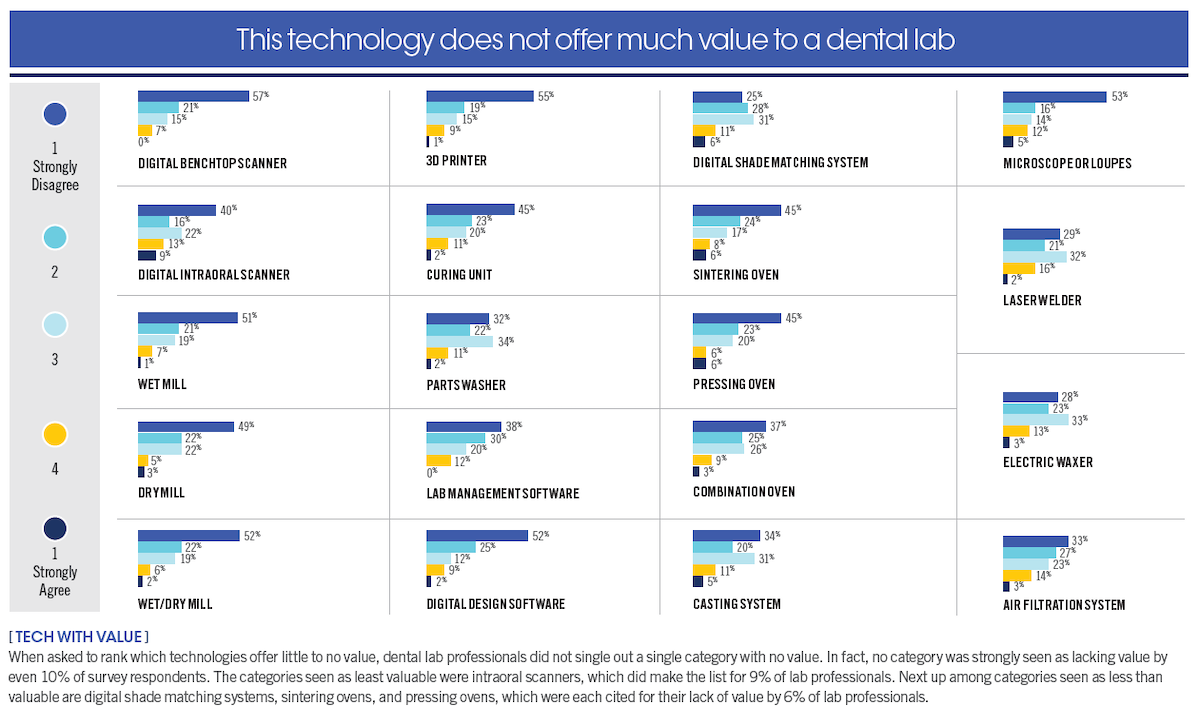

When asked to rank which technologies offer little to no value, dental lab professionals did not single out a single category with no value. In fact, no category was strongly seen as lacking value by even 10% of survey respondents. The categories seen as least valuable were intraoral scanners, which did make the list for 9% of lab professionals. Next up among categories seen as less than valuable are digital shade matching systems, sintering ovens, and pressing ovens, which were each cited for their lack of value by 6% of lab professionals.

[ Lab Technology in the Age of COVID-19 ]

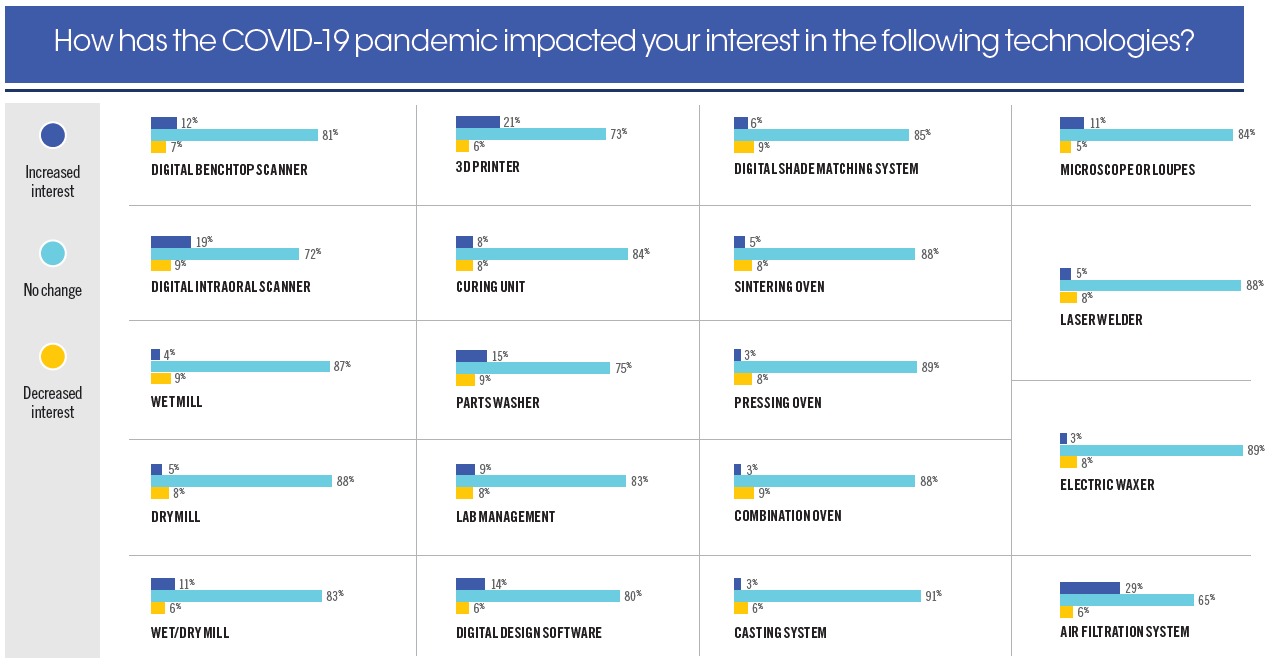

Although the COVID-19 pandemic had a massive influence on the dental lab industry in 2020, it did not make a major impact on the ways lab professionals approach technology. No single tech category saw even 10% of lab professionals say their interest in those products decreased last year. When it comes to increased interest, air filtration technologies did see increased interest from 29% of lab professionals, but 3D printers, at 21%, was the only other category that saw even 1 in 5 lab professionals say their interest has increased due to the pandemic.

[ Future Influences ]

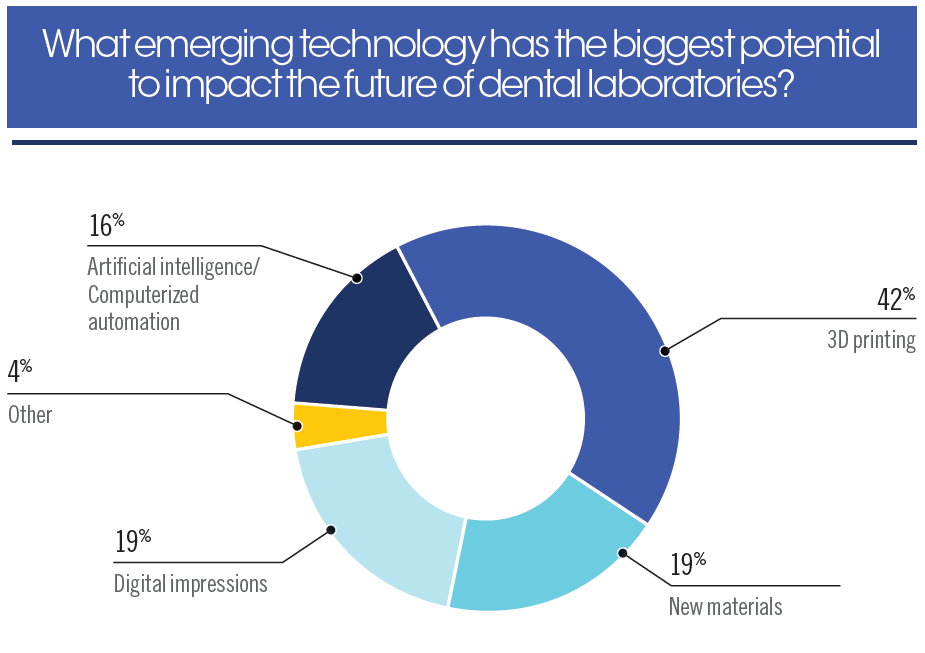

When it comes to evaluating the potential of new technologies to affect the future of the dental lab industry, there was a clear winner, as 42% of lab professionals said 3D printing is the technology that will most shape the future of the industry. Both new materials and digital impressions were cited by 19% of lab professionals, whereas 16% are most excited by the potential of artificial intelligence and computerized automation. All 4 of these technologies are likely to play a role in the shape of the lab industry’s future, just as they already are today.

[ If Money Were Not an Obstacle ]

When asked what tech was most intriguing if cost were not a consideration, lab techs and owners named a wide range of technologies, but it’s clear CAD/CAM and automated production systems are most in demand. It’s also clear that dental lab professionals are keeping an eye on the future to see which technologies are most likely to make an impact long term.

Digital scanners—both benchtop and intraoral—were the technology named most frequently, and this was followed closely by milling systems and 3D printers. But although the broad strokes of these in-demand technologies are similar, the survey responses were refreshingly specific. Sure some responses were simple technology categories, but many shared details of a desire to upgrade from a 4-axis mill to a 5-axis machine, or the need for a wet mill or a dry mill—or a milling system that can do both. When it comes to the lab professionals and the 3D printers they want, it’s clear many see the advantages of selective laser melting systems and their ability to print with metals. A few responses even looked forward to the days when there is a printer capable of additive manufacturing of zirconia restorations.

A few of the responses showed a desire for more artificial intelligence services, and robotic applications in the lab. There were also a few responses that really took the “money is no object” concept to its limits with the idea of “helicopter delivery” or the simple desire to use unlimited money to obtain, “all of it!”

Download Issue: Dental Lab Products August 2021

Download Issue: Dental Lab Products August 2021