- About Us

- Advertise

- Editorial

- Contact Us

- Terms and Conditions

- Privacy Policy

- Do Not Sell My Personal Information

© 2025 MJH Life Sciences™ and Dental Products Report. All rights reserved.

A Powerful Foundation for Denture Cases

A product roundup of some of the strongest, most esthetic denture base resins on the market today.

When crafting the perfect denture, whether it’s a partial or full arch, you and your team have a number of important considerations to keep in mind. The most important of these are probably esthetics, strength, and biocompatibility of the denture to the patient’s mouth. Different practices may prefer different materials, but it’s vital to have a good understanding of the options available to your lab when crafting denture cases.

As different materials are suited to different techniques, understanding what matches your lab’s capabilities is key to getting the best denture base result. Acrylic resins use a process in which the polymethylmethacrylate in the powder is added to a methyl methacrylate monomer in the liquid to create the base material. Technicians are then able to sculpt the denture base into the desired shape and heat cure it to set. 3D-printed denture bases are different in that the printer enacts the curing process. Materials are fed through the 3D printer, and full or partial arch cases are printed that meet the parameters and digital design. This option may be ideal for labs with efficient 3D printers, as it is said to require less time than heat curing and physical molding. Here we take a look at a few of the denture base materials available on the market now, both 3D and acrylic.

Photo courtesy of Misha/stock.adobe.com.

Lucitone 199 & HIPA

The Lucitone denture base family from Dentsply Sirona is an acrylic resin base family that boasts esthetics and strength. Lucitone 199 is suitable for tissue- and implant-supported dentures and is said to have flexural strength and impact resistance. It can be compression-packed or injected, and is microwavable if injected. Lucitone HIPA is a pourable dental acrylic built for durability. It is self-curing material and can be used to repair, rebase, and reline as well as to fabricate. Both HIPA and 199 are available in different shades.

Flexcera Base

Flexcera Base material is designed to offer strength without compromising esthetics for patients who require same-day digital dentures for everyday use. They are said to be 3 times as fracture-resistant and 2 times as moisture-resistant as other 3D resins. Using long-chain chemistry, the Flexcera workflow can produce base materials to create same-day digital dentures. This material retains denture properties without being weak and benefits from ceramic-like durability. It is formulated specifically for the EnvisionTEC 3D printer workflow and designed not to compromise on quality. A lab is said to be able to print 8 dentures in 2 hours employing this digital denture workflow.

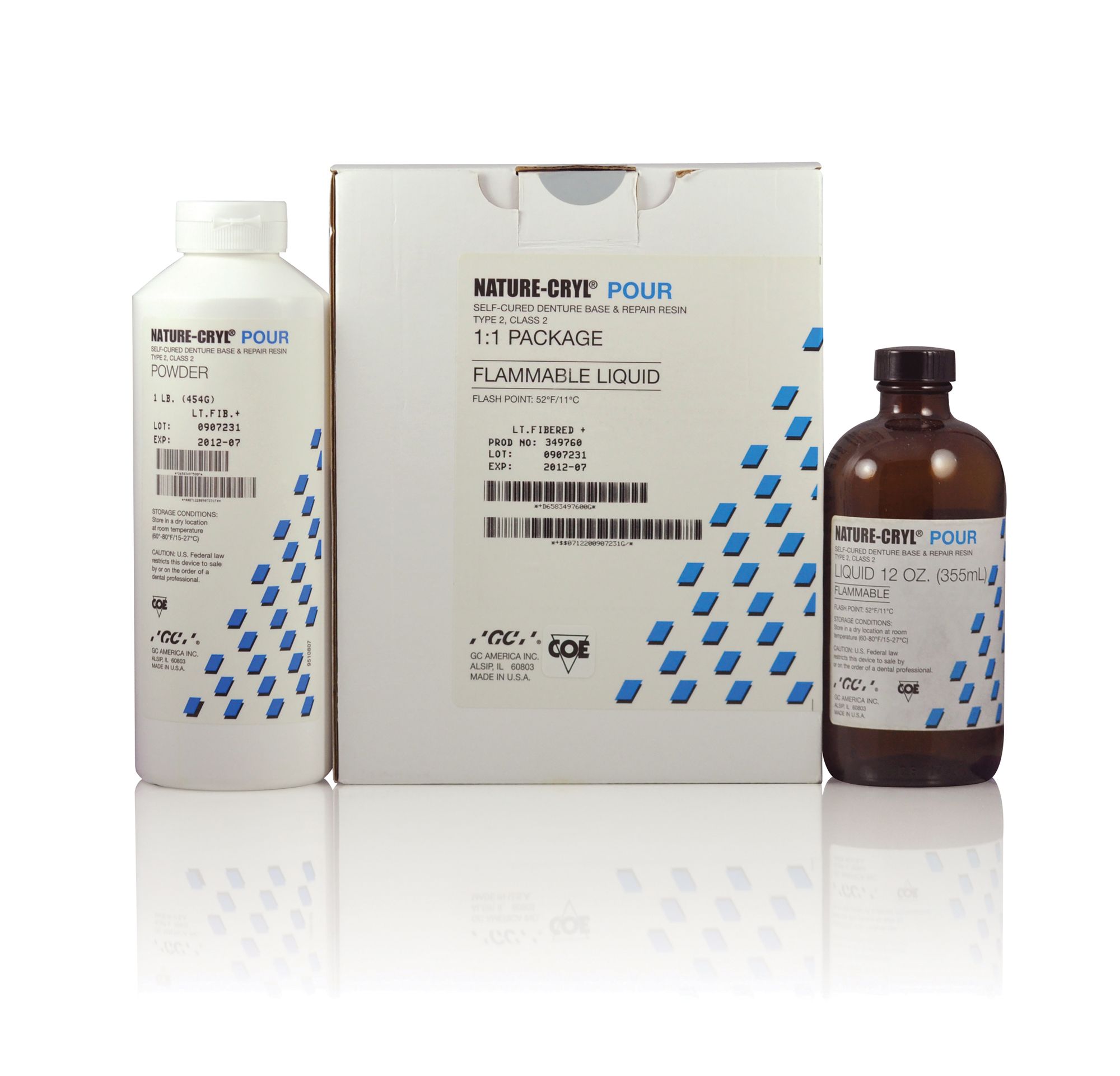

NatureCRYL

The NatureCRYL line of denture base resins from GC America has many beneficial features for denture fabrication while remaining cost-effective and accessible to many labs. The NatureCRYL line contains denture base resins for different cases: HI-20ET, MC, POUR, and SUPER HI IMPACT. Each product contains the necessary components for whatever denture base best suits the desired outcome. The NatureCRYL line also comes with computer-assisted shade-matching, designed for optimal esthetics in denture cases.

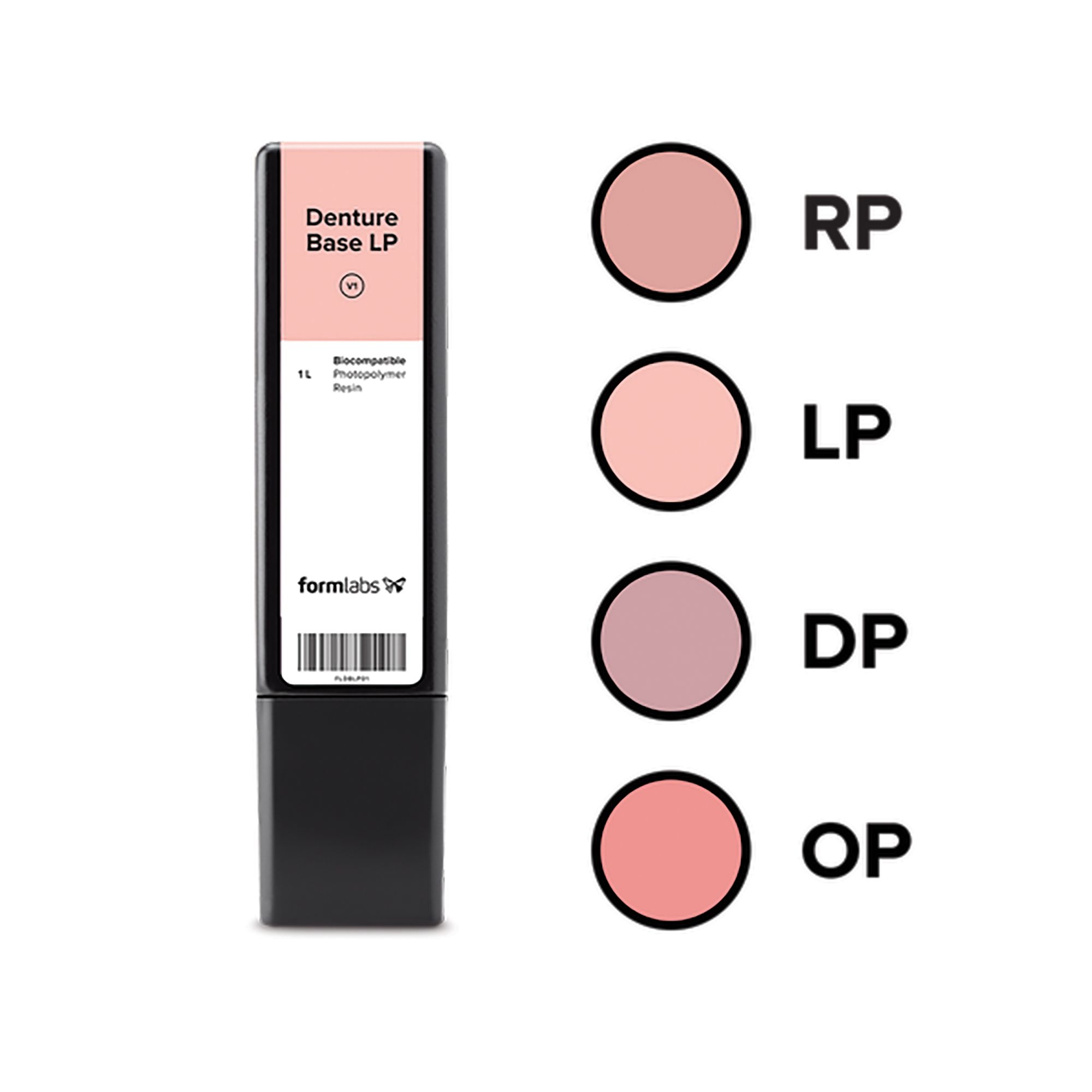

Formlabs Denture Resin

Formlabs Denture Resin is designed for 3D printers and is said to easily achieve lifelike gingiva with its 4 shades: light pink, original pink, red pink, and dark pink. This denture resin is formulated to be biocompatible, making it a good fit for any denture case brought to the lab. It is compatible with Formlabs’ 3D printers, and an application guide is available from Formlabs that explains the full digital workflow. Postcuring is required as well as a Form 2 Resin Tank LT.

KeyMill

These KeyMill discs from Keystone are high-impact acrylic discs suitable for denture base application. They are said to be strong, with enhanced esthetics and without the need for a long finishing or polishing process. They are available in 2 shades, original and light reddish pink, as well as 2 sizes: 25 mm and 30 mm. They are compatible with such 4-axis and 5-axis milling machines as VHF, Roland, and Imes-Icore, among others. This acrylic is formed using Diamond D®.

Ivotion Base

The Ivotion Denture System offers a complete digital manufacturing process for the fabrication of removable monolithic dentures, including denture base fabrication. The whole workflow combines 3Shape’s scanning capabilities and manufacturing strategies from PrograMill to create dentures using materials from Ivoclar. The Ivotion base helps to create a foundation for the digital denture. The digital system comprises an integrated workflow of digital laboratory fabrication methods, simplifying the creation of dentures and reducing opportunities for human error. Ivotion’s denture base features various gingiva shades to find the best match for each case.

Excel Formula Ultra High Heat Cure Denture Base

Suitable for patients in need of a durable denture, the Excel Formula Ultra High Heat Cure Denture Base from St. George Technology is able to withstand high impact while maintaining the flexural strength necessary for a comfortable denture base. Features include 2 shades, shade-matching repair, low residual monomer, long-term shade stability, and it is cadmium free. The Excel Formula High Heat Cure Denture Base boasts these features as well as enhanced esthetics.

Lang Denture Base Materials

This collection of denture base materials covers a plethora of requirements from dental labs. Products include the Self-Curing Denture, a denture base that auto polymerizes in 15 to 20 minutes, without the need for a traditional heat cure. There is also a High Impact-45 denture base for stronger cases, and a Premium Denture Base that comes in 6 shades for optimal gingiva shade matching, while still maintaining the strength expected from a denture. The Premium Super-20 package allows for the dense, strong denture base necessary for many denture cases.

Download Issue: Dental Lab Products February 2022

Download Issue: Dental Lab Products February 2022