Step-by-step: Fabricating temporaries with PMMA material

Luke S. Kahng, CDT, shows a technique for using PMMA material in a CAD/CAM system to fabricate highly esthetic temporaries.

We used to fabricate our temporaries with acrylic by hand, and, for higher-end long-term bridges, we would often use composite. This particular case study will explain what PMMA (defined by webopedia.com as “short for polymethylmethacrylate or, more correctly, Poly (methyl methacrylate), PMMA is a clear plastic acrylic material that can be used as a replacement for glass”) is and how we can successfully use the material in the dental world.

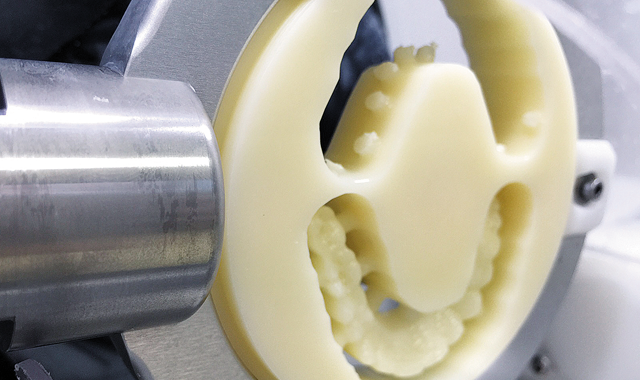

We can utilize technology, especially for implants, to create long-term temporaries through the use of a CAD/CAM machine. A good example of what we can use the material for is with a full-mouth implant case scanned and then copy scanned with a wax try-in already set up.

The exact material used in this patient’s case is called PREMIOtemp (primotecusa.com) and defined as multilayered PMMA CAD/CAM milling disks used for long-term temporary restorations, short-term provisionals and as a prototype for implant restorations.

Case Study

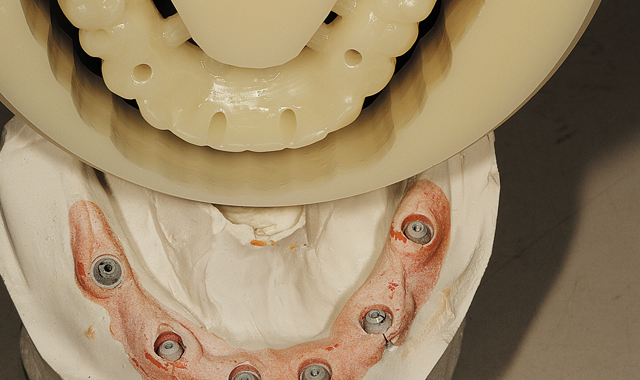

We can follow the denture wax try-in and add more pink color to create more elaborate provisionals. We can copy scan the scan and follow the incisal length, cut the gum line and make it deeper with composite then apply over the top of the gingival area. Hiossen implants had been placed in the patient’s mouth, and the dentist requested the lab fabricate very nice long-term temporaries in a screw-retained bridge restoration.

See this process step-by-step in the following slideshow.

Conclusion

It is simply amazing the changes and developments there have been in the dental lab industry even recently! We used to work mostly with acrylics but now have developed an even more sophisticated design, especially with CAD/CAM digital design technology from our own hands.

Even more options than ever are available. The good news for technicians is that machines can’t do everything! We still need our hands for our final artistic and natural touches to maximize our final product, which also increases our profit and value!